If you’re looking for a comfortable and unique way to create your own clothing designs, screen printing is for you. And, if you want to take your craft to the next level, there’s one crucial item you’ll need: an emulsion for screen printing.

Before purchasing an emulsion for screen printing, there are a few factors to consider. Firstly, the type of emulsion you’ll need depends on the type of ink you’ll be using. There are emulsions specifically made for water-based and plastisol inks, so make sure you choose the right one for your project. Secondly, consider the type of exposure and cure times you’ll need. Some emulsions require a longer exposure time or a higher wattage light source, so make sure you choose the right one for your equipment and experience level. Lastly, consider the viscosity or thickness of the emulsion. A thicker emulsion may be easier to work with, while a thinner one may provide better results.

Are you ready to create stunning designs with screen printing? Are you looking for an emulsion that will bring your designs to life? Do you want to take your craft to the next level with an easy-to-use and durable emulsion? If so, you’ve come to the right place. In this article, we’ll guide you through the ins and outs of choosing an emulsion for screen printing so you can create beautiful designs without breaking the bank or sacrificing quality. So, grab a cup of coffee and join us for an emulsion journey you won’t forget.

10 Best Emulsion For Screen Printing

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for screen printing on textiles, fabric, and silk screens using plastisol ink.

|

|

||

|

2

|

The product is ideal for removing emulsion in screen printing.

|

|

||

|

3

|

The product is ideal for beginners in screen printing to create DIY crafts with basic tools and materials.

|

|

||

|

4

|

The product is ideal for those interested in screen printing as it includes all necessary materials for a complete kit.

|

|

||

|

5

|

The product is ideal for creating photographic stencils on screens for screen printing.

|

|

||

|

6

|

Ideal for drying silk screen printing emulsion and t-shirts with an 800W machine, suitable for commercial use at 110V.

|

|

||

|

7

|

It is ideal for screen printing with photopolymer emulsion.

|

|

||

|

8

|

This product is ideal for removing emulsion stencil from screen printing screens, making it easier to clean and reuse them.

|

|

||

|

9

|

This product is ideal for screen printing and creating high-quality photographic stencils.

|

|

||

|

10

|

Screen printing enthusiasts, hobbyists or small business owners looking for a complete and affordable all-in-one kit.

|

|

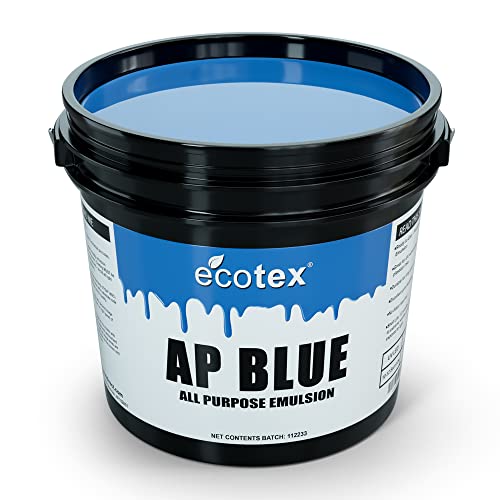

1. Eco-Silk Screen Emulsion For Printing Plastisol Ink

The AP Blue Emulsion from Ecotex is a top-quality screen printing supply that is easy to use. This emulsion is premixed and pre-sensitized, making it ready to apply to your screen printing screens straight out of the canister. It is fully compatible with all plastisol ink screen printing techniques as well as UV ink. This emulsion is ultra-durable and must be cured with a strong emulsion exposure unit. It is recommended to use an emulsion scoop coater for clean and even coverage.

This emulsion is perfect for all skill levels, whether you are a beginner or an advanced printer. It has a shelf life of 12 months and is proudly made in the USA. Moreover, this pre-sensitized photo emulsion does not require the addition of diazo and therefore has a very long shelf life of over a year. This makes it a perfect and economical silk screen emulsion for your print shop. Lastly, make sure to pick up some emulsion remover for when you are done to reclaim your screens.

- Pre-mixed and pre-sensitized for easy use

- Fully compatible with all plastisol ink screen printing techniques as well as UV ink

- Ultra-durable and must be cured with a strong emulsion exposure unit

- Perfect for all skill levels

- 12-month shelf life

- Pre-sensitized photo emulsion does not require the addition of diazo and therefore has a very long shelf life of over a year

- – DIY light is not recommended

2. 4 Pack – Nevertheless Screen Printing Scrub Brush – For Emulsion Removal

Keep your screens clean and crystal clear with the NTL Screen Cleaning Scrub Brush with Replaceable Pad – 4 pack. This product is perfect for emulsion removal and is made with high coarse bristles to ensure thorough cleaning. Each scrub brush comes with a replaceable pad that measures 5-1/2" long x 3-1/2" wide, making it easy to clean even large screens.

The handle of the NTL Screen Cleaning Scrub Brush is 5" long and is removable, allowing you to reuse it over and over. The scrub brush is also designed with a flip-over pad feature that enables you to use both sides of the pad, making it a 2 for 1 scrub. This product is shipped at a flat rate of $9.95, and orders over $150 ship free.

Say goodbye to dirty screens and hello to crystal clear ones with the NTL Screen Cleaning Scrub Brush with Replaceable Pad – 4 pack. With its high coarse bristles and removable handle, cleaning screens has never been easier!

- High coarse bristles for thorough cleaning

- Replaceable pad for easy cleaning of large screens

- Removable handle for repeated use

- Flip-over pad feature for a 2 for 1 scrub

- – None

3. Printpro Kit: 58pcs For Diy Screen Printing

The Screen Printing Tool Kit has everything you need for basic screen printing. The kit includes 50 pairs of disposable gloves, 1 Ink Knife, 2 Plastic Scrapers, 2 Hinge Clamps, 2 different sizes of Emulsion Scoop Coater, and 1 High-pressure Pneumatic Pump. The 2 Screen Printing Clamps are made of durable metal that is anti-rust and suitable for fixing wood or aluminum alloy screen printing frames. Please note that 4 screws are required for secure installation (not included). The High-pressure Pneumatic Pump is used to rinse the screen with high-pressure water, starting from the bottom to remove all emulsion and residue. The Emulsion Scoop Coater comes in 2 sizes, 15cm/5.9in and 20cm/7.87in, and is used for coating the screen. It can be said that screen coating is one of the most important parts of screen printing. The Ink Knife is 9.8in/25cm long and helps to mix and transfer the ink and emulsion.

If you're looking for a complete screen printing tool kit, this is a great option. It includes all the basic tools you need to get started, and the high-pressure pneumatic pump ensures a thorough clean. The two different sizes of Emulsion Scoop Coater are also helpful to have, giving you more flexibility in your printing process. Overall, a great value for the price.

This Screen Printing Tool Kit is perfect for beginners or those looking to upgrade their current tools. The Emulsion Scoop Coater and Ink Knife make it easy to apply and mix ink and emulsion, while the Hinge Clamps and Screen Printing Clamps keep your screen securely in place. The kit also includes 50 pairs of disposable gloves, which is a nice added bonus. The only downside is that you need to purchase 4 screws separately to secure the Screen Printing Clamps.

- Includes all the basic tools needed for screen printing

- High-pressure pneumatic pump ensures thorough cleaning

- Two different sizes of Emulsion Scoop Coater provide flexibility

- Ink Knife is helpful for mixing and transferring ink and emulsion

- Includes 50 pairs of disposable gloves

- – Requires 4 screws (not included) to secure Screen Printing Clamps

4. Screen Printing Made Easy With Pllieay!

The Upgraded Screen Printing Kit comes with everything needed to start screen printing at home. It includes a screen frame and base, silk screen printing hinge clamps, emulsion scoop coater, screen printing frames (10×14" & 8×10") with 110 white mesh, screen printing squeegee (9.4"), plastic scraper (6.8"), inkjet transparency film, mask tape, wood stick, 100ml Silicone measuring cup, plastic cups, gloves, and instructions for easy setup.

The Six-Color Ink Set consists of six cans of 6-6.5 ounce (170-180 ml) screen printing ink in black, white, red, yellow, blue, and green, as well as Photo Emulsion & Diazo. The Photo Emulsion and Diazo should be stirred before use, ideally within one month but no more than two months. The Diazo and Photo Emulsion can be stored separately for up to a year if not mixed.

The kit also includes two different-sized wooden screen printing frames (10×14" & 8×10") with two screen printing squeegees to match. These frames are ideal for different size needs and will make your DIY project easier and cleaner.

The Screen Frame Base kit comes with a base and silk screen printing hinge clamps to ensure convenience and cleanliness during your DIY project. Additionally, the kit provides a suitable Emulsion scoop coater for the screen frame, saving you time searching for a matching scoop coater.

- Complete kit with all necessary tools and materials for screen printing at home

- Six-color ink set for versatile printing options

- Different-sized frames and squeegees for various printing needs

- Screen frame base kit for convenience and cleanliness

- Suitable emulsion scoop coater provided, saving time and effort

5. Speedball Diazo Photo Emulsion, 26.4-Ounce

The Speedball Diazo Photo Emulsion & Sensitizer is perfect for artists who want to create highly detailed or photographic stencils for screen printing. With this product, artists can achieve professional-grade results without the need for expensive equipment and darkrooms. The emulsion can be easily mixed and applied under normal light conditions, but it should be kept in a dark place until it is time for exposure.

This emulsion can be used with any water-based or solvent-based ink, making it versatile and convenient for artists. Moreover, it can be easily removed from the screen with Speedball Diazo Photo Emulsion Remove, allowing artists to reclaim the screen for another use.

However, it is important to note that Speedball’s Diazo Photo Emulsion is a 2-step process where the photo emulsion needs to be activated. To activate the photo emulsion, sensitizer needs to be added. Speedball Diazo Sensitizer is sold separately.

- Allows artists to create highly detailed or photographic stencils for screen printing

- No darkroom needed, can achieve professional-grade results without expensive equipment

- Can be used with any water-based or solvent-based ink

- Easily removable from the screen with Speedball Diazo Photo Emulsion Remove

- – Speedball Diazo Sensitizer is sold separately

- – Must be activated with the sensitizer before use

6. Silk Screen Drying Cabinet – Mxbaoheng

Introducing the oven that can help you with your photoresist drying needs. Its maximum temperature can reach up to 75 degrees, although it is recommended to set it to 65 degrees for optimal use. Keep in mind that the temperature set by the meter may differ from the actual temperature by 2-3 degrees due to external factors such as room temperature and switch drawers, but this is normal and does not affect the machine's functionality.

With a drying time of 2-5 minutes, depending on the thickness and temperature of the photoresist, this oven is efficient and reliable. For a single layer of photosensitive paste, the drying time is approximately 3-5 minutes, while the time for drying the sieved version without the photosensitive paste is about 1-2 minutes.

It features a horizontal four-layer design and a stainless steel heating tube that ensures even drying of the emulsion screen. The temperature control components are imported and provide automatic constant temperature control, which adds to the machine's reliability.

The body of the oven is electrostatically sprayed for durability and corrosion resistance, so you can be sure that it is built to last.

- Efficient and reliable drying time of 2-5 minutes depending on the thickness and temperature of the photoresist

- Horizontal four-layer design with a stainless steel heating tube for even drying of the emulsion screen

- Imported temperature control components with automatic constant temperature control for added reliability

- Electrostatically sprayed body for durability and corrosion resistance

7. Chromaline Chromablue Photopolymer Emulsion For Screen Printing (Gallon)

This product is designed to deliver excellent detail and fast exposure times, making it easy to achieve accurate burns. It boasts an exceptional shelf life, so you can be confident in its reliability and consistency over time. The burn process is smooth and efficient, ensuring that your work is completed quickly and without any issues.

The product is highly versatile and can be used for a variety of applications, including medical, industrial, and scientific purposes. It is compatible with a wide range of materials and is suitable for use in both manual and automated processes.

Overall, this product is a top choice for professionals who demand precision and reliability in their work. With its exceptional performance and long shelf life, you can be confident that you are getting a high-quality product that will deliver consistent results time and time again.

- Delivers excellent detail

- Provides fast exposure times

- Boasts an exceptional shelf life

- Compatible with a wide range of materials

- Suitable for use in both manual and automated processes

8. Eco-Screen Emulsion Remover: Easy Screen Cleaning Solution.

Ecotex's Best Seller Emulsion Remover is a powerful and efficient solution that can break down two-part and pre-sensitized emulsion in seconds. It can be used in a sink or paired with screen printing washout booth for easy reclaiming of screens. The emulsion remover is strong enough to remove all types of emulsion in the shop, yet safe enough to use at home. Its formula is 100% drain safe, biodegradable and eco-friendly, making it suitable for use in silkscreen equipment, shops, and garages.

This emulsion remover is safe for all mesh and can clean any type of emulsion without the use of harsh chemicals. It comes ready to use, so you can use it right out of the bottle for tough jobs like screen printing emulsion, photo emulsion, or emulsion residue on screen printing equipment. It can also be diluted with water up to 4:1 for everyday maintenance or around the shop. The product comes in quart and gallon sizes, making it convenient for your needs.

Ecotex's Emulsion Remover is proudly made in the USA and distributed to the USA. Whether you are a veteran at screen printing or you are getting your first set of screen printing supplies, Screen Print Direct has got you covered.

- Powerful and efficient in breaking down two-part and pre-sensitized emulsion

- Can be used in a sink or paired with screen printing washout booth

- Strong enough to remove all types of emulsion in the shop, yet safe enough to use at home

- Formula is 100% drain safe, biodegradable, and eco-friendly

- Safe for all mesh and can clean any type of emulsion without the use of harsh chemicals

- Ready to use and can be diluted with water up to 4:1 for everyday maintenance or around the shop

- Comes in quart and gallon sizes, making it convenient for your needs

- Proudly made in the USA and distributed to the USA

9. Speedball Art Products 4559 Diazo Photo Emulsion Kit

Speedball’s Diazo Photo Emulsion is the perfect solution for creating detailed stencils or photographic designs for screen printing. Unlike other photo emulsions, it is a two-step process that requires activation of the photo emulsion with a sensitizer. The sensitizer is a thick oil that requires water to achieve the right consistency before adding it to the photo emulsion. (Don't worry if the sensitizer bottle feels unfilled; it is not empty!). With Speedball’s Diazo Photo Emulsion, you don't need a specialized darkroom or a light-safe environment to create your stencils. You can mix the photo emulsion under normal light conditions, making it simple and easy to use. The set comes with 6.6oz (195ml) Diazo Photo Emulsion, 2.12g Diazo Sensitizer, 8oz (237ml) Diazo Photo Emulsion Remover, and detailed instructions to ensure a hassle-free experience. The product conforms to ASTM D-4236, ensuring that it is safe and reliable. The jar contains a dried solution that requires water to dissolve the material and turn green. With Speedball’s Diazo Photo Emulsion, you can create intricate and detailed stencils for your screen printing needs with ease.

- Allows for the creation of detailed and photographic stencils for screen printing

- Easy to use two-step process

- Can be mixed under normal light conditions

- Comes with Diazo Photo Emulsion, Diazo Sensitizer, and Diazo Photo Emulsion Remover

- Conforms to ASTM D-4236 for safety and reliability

- – Requires mixing with water before use

- – May take some practice to achieve desired results

10. Speedball Advanced All-In-One Screen Printing Kit, Includes Led Uv Exposure Lamp

If you're looking for an all-in-one kit to take on the photo emulsion method of screen printing, the Speedball All-in-One Kit is a great option. This kit has everything you need to get started, including tools, inks, and a light source to expose your screen with ease. The kit is also ideal for fabric printing projects, featuring inks and tools specifically designed for this purpose.

With the Speedball All-in-One Kit, you'll receive a 10”x14” wooden screen frame and base, a craft squeegee for textile use, and four 4oz. jars of Speedball Fabric Screen Printing Ink (in black, red, white, and blue). Additionally, you'll get a 3.3oz. bottle of Speedball Diazo Photo Emulsion, a bottle of Speedball Sensitizer, and a 4oz. bottle of Speedball Photo Emulsion Remover. The kit also includes two Speedball transparencies, a lamp, a lamp clamp, four craft sticks, and a sheet of black paper.

To help you get started, the Speedball All-in-One Kit also comes with a comprehensive instruction booklet. The booklet is translated into three languages and provides step-by-step instructions that are brought to life with photos and illustrations. Whether you're a beginner or an experienced screen printer, this kit has everything you need to get started with the photo emulsion method.

- All-in-one kit includes all necessary tools, inks, and light source

- Ideal for fabric printing projects

- Comprehensive instruction booklet included

Best Emulsion For Screen Printing FAQs

How do you properly coat a screen with emulsion for screen printing?

Coating a screen with emulsion for screen printing can be a tricky task, but with the right technique and tools, it can be done effectively. Firstly, ensure that the screen is clean and free from any debris or dust particles. Use a degreaser solution to remove any oil or grease, which could affect the emulsion's adhesion.

Next, pour the emulsion onto the screen, starting at the top and working your way down. Spread the emulsion evenly using a scoop coater, ensuring that the thickness is consistent across the screen. Be careful not to overcoat, as this can lead to issues when exposing the stencil.

Once the emulsion is evenly coated, leave the screen to dry in a dark, cool environment. This ensures that the emulsion is fully cured and ready for exposure.

In summary, to properly coat a screen with emulsion for screen printing, ensure that the screen is clean, use a scoop coater to apply the emulsion evenly, and leave the screen to dry in a suitable environment. With these steps, you'll be able to create high-quality prints every time.

How do you properly reclaim a screen after using emulsion for screen printing?

After using emulsion for screen printing, reclaiming the screen is a crucial step to ensure that the screen is ready for the next printing job. To properly reclaim a screen, you need to follow a few steps.

Firstly, remove any excess ink from the screen using a spatula or scraper. Then, remove the tape from the edges of the screen and rinse it with water to remove any remaining ink.

Next, apply a screen degreaser to the screen and scrub it with a brush. This will remove any oils or dirt that may have accumulated on the screen.

After that, rinse the screen with water again to remove the degreaser and any remaining ink or debris. Then, apply a stencil remover to the screen and let it sit for a few minutes.

Finally, use a pressure washer or a high-pressure hose to rinse the screen thoroughly, ensuring that all of the stencil remover and emulsion are removed.

By following these steps, you can properly reclaim a screen after using emulsion for screen printing, ensuring that it is clean and ready for your next printing job.

What are the different types of emulsions available for screen printing?

Screen printing is a popular printing technique that involves the use of emulsions to create a stencil on a screen. Emulsions are substances that contain two immiscible liquids that are mixed together to create a suspension. When applied to a screen, emulsions allow ink to pass through the open areas of the stencil and onto the substrate below. There are several different types of emulsions available for screen printing, including:

1. Diazo emulsions – These emulsions are made by mixing diazo powder with a liquid emulsion. They are popular because they are easy to use and can be used with a wide range of inks.

2. Dual-cure emulsions – These emulsions are made by mixing two different chemicals together. They are popular because they provide a very durable stencil that can withstand multiple print runs.

3. Photopolymer emulsions – These emulsions are made by exposing a photosensitive emulsion to UV light. They are popular because they provide a very fine level of detail and can be used with a wide range of inks.

4. Water-resistant emulsions – These emulsions are designed to resist water, making them ideal for printing on fabrics that will be washed or exposed to moisture.

Overall, the type of emulsion you choose will depend on your specific printing needs and the type of ink you plan to use. It's important to choose an emulsion that is compatible with your ink and substrate to ensure the best possible results.

What is an emulsion and how is it used in screen printing?

An emulsion is a photo-sensitive liquid that is used in the screen printing process to create a stencil. This stencil is used to transfer the design or image onto the printing surface. The emulsion is a mixture of two components: the sensitizer and the base. The sensitizer is a light-sensitive chemical that reacts to light, while the base is a thick, viscous liquid that holds the sensitizer in suspension.

To use emulsion in screen printing, the first step is to coat a screen with a thin layer of the emulsion. This is done by pouring the emulsion onto the screen and using a squeegee to spread it evenly. The coated screen is then left to dry in a dark room. Once it is dry, the screen is exposed to a light source with the image or design to be printed placed on top. The light causes the sensitizer in the emulsion to harden, creating a stencil. The unexposed areas of the emulsion are then washed away with water, leaving only the hardened stencil behind.

The stencil can then be used to print the image or design onto the desired surface by placing the screen on top of the surface and using a squeegee to push ink through the stencil and onto the surface. Emulsion is a versatile and widely used tool in the screen printing industry, allowing for precise and detailed prints to be created with ease.

What is the exposure process for emulsion in screen printing?

The exposure process for emulsion in screen printing is a critical step that ensures the design or image is accurately transferred onto the screen for printing. The process involves coating the screen with a photosensitive emulsion, which is then exposed to UV light through a film positive or digital negative. The light hardens the emulsion in areas where the design is present on the film, leaving the rest of the emulsion soft and washable.

After exposure, the screen is washed with water or a special emulsion remover, which removes the soft emulsion, leaving behind a stencil of the design on the screen. This stencil is then used to transfer ink onto the desired material, either by hand or with a machine.

The exposure process is crucial for achieving high-quality prints, as any errors or inconsistencies during this step can result in a flawed print. It requires attention to detail, proper equipment, and skillful execution to ensure the emulsion is exposed accurately and consistently.