If you’re looking for an efficient and reliable way to fasten deck boards, screws are the perfect solution. Unlike nails, screws can provide a tighter and more secure grip that lasts longer. However, with so many options available, selecting the right screws for deck boards can be overwhelming.

Before buying screws for deck boards, there are several factors to consider. First, the material of your deck boards is essential. Are they made of hardwood, composite, or softwood? Different materials require different types of screws, and you want to make sure you choose the right ones. Second, think about the length and size of the screws. Deck boards come in different sizes, and you’ll want to ensure that the screws are long enough to go through the board and into the joist. Finally, check the corrosion resistance of the screws. They will be exposed to various weather conditions, so choosing screws that can withstand rust and corrosion is essential.

Are you tired of nails popping up on your deck and ruining its look? Do you want to make sure your deck boards are safely fastened for years to come? In this article, we’ll guide you through the process of selecting the best screws for your deck boards. We’ll cover everything from screw material to size and corrosion resistance, so you can make an informed decision. Keep reading to find out more!

10 Best Screws For Deck Boards

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

This product is ideal for fastening decking materials with a 5/32" gap, including hardwood, thermal, and composite decks.

|

|

||

|

2

|

This product is ideal for edge fastening installation on narrow board decks with 3/16" spacing and 3-1/4 to 5" width.

|

|

||

|

3

|

This product is ideal for hidden deck fastening with a protective coating, providing durability and aesthetic appeal.

|

|

||

|

4

|

Ideal for securing trailer floorboards and decks with a Torx driver.

|

|

||

|

5

|

Ideal for securing trailer floorboards and deck boards with a T40 Torx driver.

|

|

||

|

6

|

The product is ideal for securing trailer floorboards and decks with its flat head, T40 Torx 6-Lobe design.

|

|

||

|

7

|

This product is ideal for securing trailer floorboards or decks with its Torx 6-Lobe Flat Head design.

|

|

||

|

8

|

This product is ideal for securing trailer floorboards and deck structures with a T40 Torx 6-Lobe Flat Head.

|

|

||

|

9

|

The product is ideal for fastening wood flooring boards together with minimal spacing and high durability for outdoor decking.

|

|

||

|

10

|

The product is ideal for attaching floorboards and decks in trailers with a Torx 6-Lobe flat head design.

|

|

1. Black Extreme Deck Fasteners For Hardwood And Composite

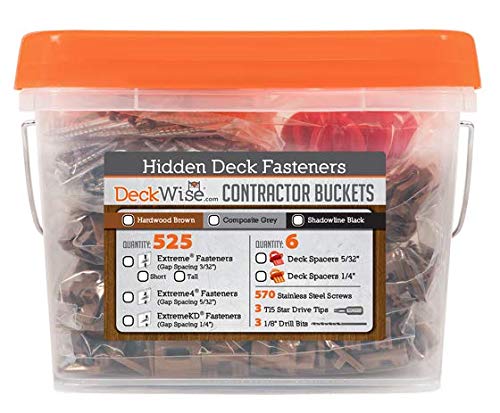

The hidden fastener kit is a perfect solution for automatically spacing deck boards at 5/32" (4mm) distance. This kit contains 525 hidden fasteners, 570 #8×2" T15 stainless steel screws, 3 1/8" high-speed drill bits, 3 T15 star driver tips, 6 5/32" spacer tools, and an instruction sheet. The fasteners are manufactured from polyethylene with stainless steel black oxide insert, which reduces fastener tilting during installation and improves gap consistency. This kit can be used with air/kiln dried hardwood, composite, or PVC decking.

The hidden fastener kit ensures easy installation of deck boards with consistent spacing. The screws and fasteners are made from high-quality stainless steel, making them durable and long-lasting. The kit includes all the necessary tools and instructions to make installation a breeze. The polyethylene construction of the fasteners makes them resilient and resistant to wear and tear, ensuring longevity. The fasteners hold the deck boards in place securely, reducing the chance of any movement or damage. The fasteners are hidden, making for a sleek and professional finish.

In summary, the hidden fastener kit is an excellent solution for achieving consistent spacing and a professional finish while installing deck boards. The kit is easy to use, durable, and long-lasting, making it an excellent investment for any decking project.

- Automatically spaces deck boards at 5/32" (4mm)

- Manufactured from polyethylene with stainless steel black oxide insert

- Reduces fastener tilting during installation improving gap consistency

- For use with air/kiln dried hardwood, composite, or PVC decking

- Includes all necessary tools and instruction sheet for easy installation

- Sleek and professional finish with hidden fasteners

2. Narrow Board Deck Installation Kit

The Marksman PRO-NB Tool is an all in one kit that comes with (1750) 2-3/8" Edge Screws and 2 replacement driver bits, which makes it ideal for those who want a hassle-free installation process. The tool features hidden edge fastening, which allows for the installation of two patented CAMO Edge Deck Screws through the edge of the deck board, not the surface. This feature reduces splitting and cracking, making it perfect for exclusive use with CAMO Edge Deck Screws that auger material out.

The tool is designed to fit any 3-1/4 in. (83mm) to 5 in. (127mm) deck board, making it ideal for narrow board treated lumber, cedar, hardwood, composite, and PVC decking. The automatic spacing feature creates 3/16 in. (5mm) spacing, which ensures uniform spacing between the deck boards. Additionally, the tool comes with an auto depth drive feature that has a built-in shoulder on the driver bits, which prevents over-driving. However, it's important to note that driver bits are not included with this tool.

This Marksman PRO-NB Tool is a versatile and efficient tool that can be used for installing deck boards quickly and easily. It's perfect for DIY enthusiasts and professionals alike and is sure to make your deck installation process a breeze.

- All in one kit that comes with (1750) 2-3/8" Edge Screws and 2 replacement driver bits

- Hidden edge fastening reduces splitting and cracking

- Automatic spacing creates uniform spacing between the deck boards

- Auto depth drive feature prevents over-driving

- – Driver bits are not included with the tool

3. Camo Edge Deck Screws, Hidden Fastening, 1-7/8", Protech Coated (1750 Ct)

The Hidden Fastener System is an innovative way to securely attach deck boards to the joist without any visible fasteners, ensuring a fastener-free deck surface. The screws are inserted through the edge of the deck board, and the rake tip augers material out, which helps to reduce splitting and cracking. The screws are coated with Protech, making them ideal for use with treated lumber, composite, capped composite, and PVC deck boards. This system covers an area of approximately 500 sq ft and is recommended for use with boards that are ¾-inch to 1-inch thick, using 1-⅞-inch (48mm) Edge Deck Screws. For best results, use with the Marksmen System, which includes Pro, Pro-X1, Pro-NB, and Edge Guides from CAMO.

- Fastener-free deck surface

- Reduces splitting and cracking

- Ideal for treated lumber, composite, capped composite, and PVC deck boards

- Covers approximately 500 sq ft

- Easy to use with the Marksmen System

4. (400) 1/4-20×2 1/4 Flat Head Trailer Floorboard Deck Screws T30 Torx Plain

Looking for a durable and reliable 1/4-20 inch thread cutting screw? Look no further than this product with a length under head of 2-1/4 inches. Made from high-quality case hardened steel, this screw is sure to last for years to come. With a type F thread cutting pattern and full thread, it is easy to use and offers a secure hold. The T30 6 lobe drive size ensures easy installation and removal. This screw comes with a plain and oil finish for added protection against wear and tear.

When you need a strong and long-lasting screw for your project, this product is an excellent choice. With its durable materials and precision design, it offers a secure hold and easy installation. Whether you are working on a DIY project at home or a professional construction job, this screw is up to the task.

This product is also versatile, suitable for use in a variety of applications. Its 1/4-20 inch diameter and 2-1/4 inch length make it an ideal choice for a range of projects, from woodworking to metalworking and more. Plus, with its type F thread cutting pattern and full thread, it is easy to use and offers a secure hold. So why wait? Order this product today and get started on your next project!

- Made from high-quality case hardened steel for durability and reliability

- Type F thread cutting pattern and full thread for easy use and secure hold

- T30 6 lobe drive size for easy installation and removal

- Plain and oil finish for added protection against wear and tear

- Suitable for use in a variety of applications

5. (250) 5/16"-18 X 2" T40 Torx 6-Lobe Flat Head Trailer Floorboard Deck Screw – By Fastener Depot, Llc

The Type F Point is a 6-Lobe Drive screw with a T40 Drive Size. It is made of high-quality Carbon Steel, which makes it strong and durable. This screw is perfect for use in a variety of applications, such as decking, roofing, and framing.

The 6-Lobe Drive provides a secure grip, preventing slippage during installation. The T40 Drive Size ensures compatibility with a wide range of tools, making it easy to use. The Type F Point is designed to penetrate wood quickly, reducing installation time and effort.

Carbon Steel is known for its strength and durability, making the Type F Point screw resistant to wear and tear, corrosion, and rust. It is also an environmentally friendly option, as it can be recycled at the end of its life cycle.

- Made of high-quality Carbon Steel for strength and durability

- 6-Lobe Drive provides a secure grip

- T40 Drive Size ensures compatibility with a wide range of tools

- Designed to penetrate wood quickly, reducing installation time and effort

- Resistant to wear and tear, corrosion, and rust

- Environmentally friendly option that can be recycled at the end of its life cycle

6. Fastener Depot's Trailer Deck Screws

The Type F Point with 6-Lobe Drive and T40 Drive Size is a high-quality fastener made of carbon steel. It is designed to provide a secure and reliable connection for a wide range of applications. The Type F Point is known for its sharp and pointed tip, which makes it easy to penetrate hard materials. The 6-Lobe Drive ensures a strong grip, preventing the fastener from slipping or stripping during installation. The T40 Drive Size is a standard size that fits most power tools, making it easier and faster to install.

This fastener is made of carbon steel, a strong material that can withstand high loads and resist corrosion. It is suitable for use in outdoor and indoor environments, and can be used in a variety of materials, such as wood, plastic, and metal. The Type F Point with 6-Lobe Drive and T40 Drive Size is also easy to remove, thanks to its unique design that allows for quick and easy extraction.

Whether you're a DIY enthusiast or a professional contractor, the Type F Point with 6-Lobe Drive and T40 Drive Size is a great choice for your next project. Its high-quality construction, reliable performance, and versatility make it a must-have for any toolbox.

- Made of carbon steel, a strong and corrosion-resistant material

- Sharp and pointed tip for easy penetration of hard materials

- 6-Lobe Drive ensures a strong grip to prevent slipping or stripping during installation

- T40 Drive Size fits most power tools for faster and easier installation

- Easy to remove thanks to its unique design

7. Fastdeck 6-Lobe Trailer Screws

The Type F Point 6-Lobe Drive T40 Drive Size Carbon Steel is a reliable and durable screw that is perfect for various applications. It is made of high-quality carbon steel which makes it tough and capable of withstanding harsh environments. The screw features a Type F point that provides excellent grip and reduces the chances of slipping during installation. The 6-Lobe Drive T40 Drive Size ensures that the screw can be easily and securely fastened without any stripping or slipping.

The screw is designed to provide a tight and secure fit that ensures that the joint remains stable and strong. The T40 Drive Size ensures that the screw can be easily installed using standard tools. The screw is also corrosion resistant which ensures that it can be used in both indoor and outdoor applications. Its carbon steel construction also makes it capable of withstanding high temperatures without losing its strength and structural integrity.

This Type F Point 6-Lobe Drive T40 Drive Size Carbon Steel screw is an excellent choice for various applications such as metalworking, woodworking, and construction. It is a reliable and durable screw that is easy to install and provides a secure and stable joint. Its carbon steel construction ensures that it can withstand harsh environments and high temperatures without losing its strength and structural integrity. Overall, this screw is an excellent investment that provides great value for money.

- Made of high-quality carbon steel

- Excellent grip and reduces the chances of slipping during installation

- Designed to provide a tight and secure fit

- Corrosion resistant and can be used for both indoor and outdoor applications

- Can withstand high temperatures without losing its strength and structural integrity

- Easy to install and provides a secure and stable joint

8. Topdex Outdoor Decking Fasteners – 200 Clips.

Create a professional-looking deck or balcony flooring with the help of these plastic fasteners. These clips are designed to mount your boards to the joists while keeping screws hidden from sight. You can maintain a consistent gap spacing of 0.19 inches in between your terrace boards for a streamlined look.

Installation is made easy with these decking clips. Simply insert the clip into the side groove of your decking board, drive the screw with your drill, and you're done. This saves you a considerable amount of time, effort, and energy in building your deck.

These decking fasteners are crafted to last. Made of tough plastic, the clips are durable and will not easily break. The screws are made of stainless steel, ensuring that they can withstand rust and corrosion.

With unbeatable value, you get the most out of your money whenever you purchase these decking fastener clips. Each pack comes with plastic fasteners and stainless steel mounting screws.

- Professional-looking deck or balcony flooring

- Maintains a consistent gap spacing of 0.19 inches

- Easy to install and saves time, effort, and energy

- Durable and long-lasting

- Comes with unbeatable value

9. Fastdeck Torx Trailer Screw.

The Type F Point 6-Lobe Drive T40 Drive Size Carbon Steel screw is a versatile and reliable fastener that can be used in a variety of applications. Made from high-quality carbon steel, this screw is designed to provide excellent durability and strength, making it ideal for use in demanding environments.

The 6-Lobe Drive design ensures that the screw can be easily and securely installed using a T40 Drive Size tool, making it a convenient choice for both professionals and DIY enthusiasts. The Type F Point allows for effortless installation into a range of materials, including wood, plastic and metal.

This screw is suitable for use in a range of applications, including construction, woodworking, and metalworking. It is available in various lengths and quantities to suit your specific needs.

Overall, the Type F Point 6-Lobe Drive T40 Drive Size Carbon Steel screw is an excellent choice for those looking for a versatile and reliable fastener that can provide excellent durability and strength in a range of applications.

- Made from high-quality carbon steel for excellent durability and strength.

- 6-Lobe Drive design ensures easy and secure installation with a T40 Drive Size tool.

- Type F Point allows for effortless installation into a range of materials.

- Suitable for use in a range of applications, including construction, woodworking, and metalworking.

Best Screws For Deck Boards FAQs

Can I use drywall screws for attaching deck boards?

Using drywall screws for attaching deck boards is not recommended as they are not designed for outdoor use and may rust or corrode over time. Deck boards need strong and durable fasteners to hold them in place and withstand the weight of people and furniture. The best option for attaching deck boards is using stainless steel or coated deck screws, which are specifically designed for outdoor use and can resist corrosion and rust.

Using inappropriate screws can lead to safety hazards, such as the deck boards becoming loose or even collapsing, which can cause injury or damage to property. It is important to always use the correct fasteners and follow the manufacturer's instructions when building a deck. Investing in quality screws may cost more initially, but it will save you time and money in the long run by avoiding costly repairs or replacements.

How long should the screws be for attaching deck boards?

The length of screws for attaching deck boards depends on the thickness and material of the boards. Typically, for 1-inch thick wooden deck boards, 2 1/2 -inch long screws are used. For composite deck boards, 2 1/4 -inch long screws are usually recommended. It's essential to use the correct length of screws to avoid causing damage to the boards or the deck frame. Using screws that are too short may not hold the boards securely, while screws that are too long may split the boards. Therefore, it's important to follow the manufacturer's recommendations or consult with a professional to determine the appropriate screw length for your specific deck project. Moreover, using high-quality screws that are rust-resistant and designed for outdoor use is recommended to ensure the longevity and safety of your deck.

Should I use coated or stainless steel screws for deck boards?

When it comes to choosing the right screws for your deck, there are a few considerations that you should keep in mind. One of the main factors is the type of material that you will be using for your deck boards. In this case, you are considering whether to use coated or stainless steel screws.

Coated screws are a popular choice for decking projects as they offer good corrosion resistance and are generally more affordable than stainless steel screws. The coating on the screws helps to protect them from moisture, which can cause rust and corrosion over time. However, it's important to note that the coating can wear off over time, particularly in areas with high foot traffic or exposure to the elements.

Stainless steel screws, on the other hand, are more expensive but offer superior corrosion resistance. They are an excellent choice for decks that are located near the coast or in areas with high humidity. Stainless steel screws are also a good choice if you want a long-lasting deck that requires minimal maintenance.

Ultimately, the decision between coated or stainless steel screws will depend on your budget, the location of your deck, and your personal preferences. Both types of screws can be used successfully for deck boards, so it's up to you to decide which one is the best fit for your project.

What spacing should I use for deck board screws?

When it comes to installing deck boards, spacing is a crucial factor to consider. Proper spacing ensures that the boards are properly ventilated, reducing the risk of rot and moisture damage. Additionally, it ensures that the boards are held securely in place, preventing warping and buckling.

When it comes to choosing the spacing for deck board screws, the general rule of thumb is to leave a gap of about 1/8 inch between the boards. This gap allows for proper ventilation and drainage, which is essential for maintaining the longevity of your deck.

However, it's important to note that the specific spacing required may vary depending on the type of wood you're using, as well as the climate and environment in which your deck is located. It's always a good idea to consult with a professional or refer to the manufacturer's guidelines to ensure that you're using the appropriate spacing for your particular situation.

In summary, proper spacing is critical when it comes to installing deck board screws. By leaving a gap of about 1/8 inch between the boards, you can help ensure the longevity and stability of your deck.

What type of screws are best for securing deck boards?

When it comes to securing deck boards, there are a few types of screws that are commonly used. The most popular option is #8 or #10 stainless steel screws, as they are durable and resistant to corrosion. These screws come in a variety of lengths, so you can choose the size that best fits your deck boards.

Another option is deck screws, which are specifically designed for use in decking projects. These screws have a special thread design that helps to prevent splitting and ensure a secure hold. They also often have a larger head, which helps to prevent the screw from sinking too deeply into the wood.

Ultimately, the type of screw you choose will depend on the type of wood you are using for your deck, as well as the specific design of your project. No matter what type of screw you choose, be sure to follow best practices for installation, including pre-drilling holes and spacing the screws properly to ensure a secure and long-lasting hold.