If you're looking for the best ripping chain for milling, you're in the right place. Whether you're a professional lumberjack or a DIY enthusiast, finding the right chain for your milling needs is essential. With so many options on the market, it's important to consider a few key factors before making your purchase.

First and foremost, you'll want to consider the size and type of chainsaw you'll be using. Different chains are designed for different chainsaws, so make sure to check the compatibility before making your decision. Additionally, you'll want to consider the length and gauge of the ripping chain, as well as the number of drive links. These factors will determine the performance and efficiency of the chain in milling applications.

Next, it's important to consider the quality and durability of the chain. Look for chains made from high-quality materials that are designed to withstand the rigors of milling. You'll also want to consider the design of the chain, such as the depth gauge and tooth configuration, as these features can have a significant impact on the cutting performance.

Still not sure which ripping chain is the best fit for your milling needs? Ask yourself these questions: What type of wood will you be milling? How frequently will you be using the chain? Do you prioritize speed or precision in your milling applications? By considering these questions, you can narrow down your options and make an informed decision.

In conclusion, finding the best ripping chain for milling requires careful consideration of factors such as chainsaw compatibility, chain specifications, and cutting performance. By taking the time to evaluate your needs and ask the right questions, you can find a chain that will provide optimal results in your milling endeavors.

10 Best Ripping Chain For Milling

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

This product is ideal for replacing the chainsaw chain on Stihl MS250 and MS251 models.

|

|

||

|

2

|

The product is ideal for efficient and precise ripping cuts with a chainsaw on various materials.

|

|

||

|

3

|

The product is ideal for cutting through wood efficiently with a Stihl chainsaw.

|

|

||

|

4

|

The 8TEN Ripping Chainsaw Chain is ideal for heavy-duty cutting and efficient chainsaw operation.

|

|

||

|

5

|

The product is ideal for cutting through wood quickly, efficiently, and with ease.

|

|

||

|

6

|

The product is ideal for providing high-quality, durable chainsaw chains specifically designed for Stihl MS260, MS390, MS360, and MS310 models.

|

|

||

|

7

|

The Oregon 72RD114G 114 Drive Link 3/8-Inch Ripping Chain is ideal for cutting through wood with precision and speed.

|

|

||

|

8

|

The product is ideal for cutting through wood and performing heavy-duty tasks with chainsaws.

|

|

||

|

9

|

Ideal for cutting through tough materials with precision and efficiency, improving performance and productivity in heavy-duty chainsaw tasks.

|

|

||

|

10

|

The product is ideal for replacing chainsaw chains with a 24" length and 3/8" pitch.

|

|

1. 8ten 16 Inch Chainsaw Chain For Stihl

Introducing the Chainsaw Chain Specs – a reliable and high-quality chain designed to enhance the performance of your chainsaw. With its 16-inch length, 67 drive links, .325-inch pitch, and .063-inch gauge, this chain is built to handle tough cutting tasks with ease.

One of the standout features of this chain is its suitability for ripping. Whether you're a professional logger or a DIY enthusiast, this chain will deliver exceptional results when it comes to creating smooth and precise cuts. Please ensure compatibility with your machine before making a purchase to guarantee a perfect fit.

When it comes to replacing OEM parts, this chain is a top choice. It replaces Oregon part numbers 22BPX067G, 22LPX067G, 22LGX067G, F67-21, L67-21, V67-21, L67, and V67. It is also compatible with Husqvarna H28-67, 5018417-67, 591104267, and H26-67. Additionally, it can be used with Stihl 26RS367E, 26RS67E, and 36390050067 models.

Furthermore, this chain is compatible with a wide range of Stihl chainsaw models, including the MS360 QS, MS361 (C-B,QS), and MS390. It is also suitable for Stihl 024 (Super), 026 (PRO,P), 028 (Super), 029, 030, 031, 032, 034 (SUPER), 036 (PRO,QS), 039, and 040. Additionally, it can be used with Stihl MS260, MS260 Pro, MS261, MS261 C-M, MS261 C-MQ, MS261 CQ, MS270, MS270 C, MS270 C-B, MS270 CQS, MS271, MS280, MS280 C-BQ, and MS280 CQS models.

When it comes to durability and performance, this chain is a reliable choice. It is designed to withstand heavy use and provide consistent cutting power, ensuring that your chainsaw operates at its best. With its precise engineering and high-quality materials, this chain offers long-lasting performance that won't disappoint.

2. 8ten Chainsaw Chain For Husqvarna & Jonsered, 20 Inch

Introducing the Chainsaw Chain Specs – a reliable and high-quality replacement chain for your chainsaw. With its 20-inch length and 80 drive links, this chain is designed to provide optimal performance and durability. The .325-inch pitch and .050-inch gauge ensure precise cutting and smooth operation.

Please take a moment to verify the fitment of this chain with your machine to ensure compatibility. The chainsaw chain is compatible with various models, including Husqvarna, Stihl, Craftsman, and Jonsered. It replaces OEM part numbers such as Husqvarna H22-80, 501 84 06-80, 501 84 08-80, 591095780, H23-80, 581643680, H30 80, SP33G-80, 591095778, H23-78, Stihl 23RM380E, 23RS380E, 23RS80E, and 3637 005 0080.

For Husqvarna chainsaws, this chain is compatible with models such as 440 (E), 445 (E), 450 (50th Anniversary, E), 455 (RANCHER), 340E (SE, SG), 345, 346 (XP, XPG), 350, 351, 353 (E-TECH, G E-TECH), 455E RANCHER, 460 (RANCHER), 49, 50, and 543XP (XPG). If you own a Craftsman chainsaw, rest assured that this chain is compatible with models 358.38200, 360.35200, 360.35201, 41AY462S793, CMXGSAMY462S, and S205.

The Chainsaw Chain Specs also work seamlessly with Stihl chainsaw models 2014, 2016, 2035, 2036, 2036 Turbo, 2040, 2040 Turbo, 2050, 2050 Turbo, 2137, 2138, 2145, 2149, 2149 Turbo, 2150, 370, 410, 420, 425, 435, 45, 450, 451, 455, 49, 50, 51, 510, 52, 521, CS 2050, and CS 2050. Jonsered chainsaw models such as CS 2150, CS 2152, CS 2145, CS 2149, CS 2159, CS 2141, CS 2147, CS 2153, CS 2141, and CS 2149 can also benefit from this chain.

When it comes to chainsaw chains, durability and performance are of utmost importance. The Chainsaw Chain Specs deliver on both fronts, ensuring smooth cutting and extended longevity. Whether you're a professional or a DIY enthusiast, this chain is perfect for various cutting applications, including woodwork, tree maintenance, and landscaping.

Upgrade your chainsaw with the Chainsaw Chain Specs and experience the difference in performance and reliability. Trust in its compatibility with multiple chainsaw models and its ability to handle various cutting tasks. Don't settle for subpar chainsaw chains when you can have a premium replacement like the Chainsaw Chain Specs.

3. Oregon 72rd091g 91 Drive Link 3/8-Inch Ripping Chain, Standard Sequence

Introducing the 72RD Chainsaw Chain, a reliable and efficient tool for all your cutting needs. With its 3/8" pitch and .050" gauge, this chain is designed to deliver precise and clean cuts every time.

One of the key features of the 72RD Chainsaw Chain is its compatibility with standard chassis and cutter parts. The only difference lies in the cutter grind, ensuring a distinct performance from other chains. This makes it a perfect choice for chain-type sawmills, providing optimal results in a professional setting. However, it is not recommended for hand-held use.

To ensure smooth operation and longevity, the 72RD Chainsaw Chain is equipped with LubriLink tie straps. These tie straps play a crucial role in keeping the chain lubricated by directing the oil exactly where it's needed – on the chain. This feature enhances the overall performance of the chain, allowing for efficient cutting without any interruptions.

In addition, the 72RD Chainsaw Chain boasts a Vibe-Ban chassis design. This innovative design reduces vibrations by an impressive 25-percent or more at the handles. This not only enhances user comfort but also contributes to increased precision and control during operation. Say goodbye to the discomfort and fatigue caused by excessive vibrations, and enjoy a more enjoyable and productive cutting experience.

Whether you are a professional sawmill operator or an avid DIY enthusiast, the 72RD Chainsaw Chain is a must-have tool. Its outstanding parameters, including the 3/8" pitch and .050" gauge, ensure exceptional performance and durability. The compatibility with standard chassis and cutter parts makes it a versatile choice for various applications.

Investing in the 72RD Chainsaw Chain means investing in quality and reliability. Its innovative features, such as the LubriLink tie straps and Vibe-Ban chassis design, deliver superior cutting performance while minimizing vibrations. Trust in this chain to meet your cutting needs with precision, efficiency, and comfort.

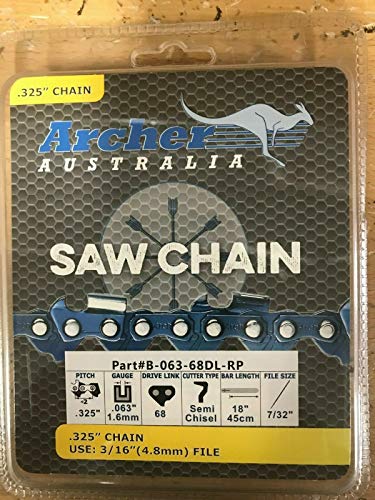

4. 8ten Ripping Chainsaw Chain 18 Inch .063 .325 74dl For Stihl Ms260 Ms390 Ms360 Ms310 (2 Pack)

Introducing the Chainsaw Chain Specs – an 18 Inch Chain designed with precision and durability in mind. With 74 Drive Links, a Pitch of .325 Inch, and a Gauge of .063 Inch, this chain is perfect for your cutting needs.

This Chainsaw Chain is specifically designed for ripping, ensuring smooth and efficient cutting every time. To ensure compatibility, please verify fitment with your machine before purchasing.

Replaces OEM Part Numbers: Oregon 22BPX074G, 22LPX074G, 22LGX074G, L74-21, F74-21, V74-21, L74, V74; Husqvarna H28-74, 501 84 17-74, 591104274, H26-74; Stihl 26RS374E, 26RS74E, 3639 005 0074.

Compatible with a wide range of Stihl models including MS 290, MS 291 (C-BEQ), MS 310, MS 341, MS 360 (C, Pro, QS), MS 361 (C-B, QS), MS 390. It is also compatible with Stihl MS 261 C-M (C-MQ, CQ), MS 270 (C, C-B, CQS), MS 271, MS 280 (C-BQ, CQS).

Additionally, this Chainsaw Chain is compatible with Stihl models 024, 024 Super, 026, 026 PRO, 026P, 028, 028 Super, 029, 030, 031, 032, 034, 034 SUPER, 036, 036 PRO, 036 QS, 039, 040, MS 260, MS 260 Pro, MS 261.

With its high-quality construction and precise specifications, this Chainsaw Chain is built to deliver reliable performance and long-lasting durability. It is the perfect replacement for your worn-out or damaged chain.

Whether you are a professional lumberjack or a DIY enthusiast, this Chainsaw Chain is a must-have for all your cutting tasks. Don't let a dull or inadequate chain slow you down – invest in the Chainsaw Chain Specs today and experience the difference it can make in your cutting efficiency.

5. Oregon 72rd114g 114 Drive Link 3/8-Inch Ripping Chain, Standard Sequence, Silver

Introducing the 72RD Chainsaw Chain, a reliable and sturdy accessory for chain-type sawmills. This chain features a 3/8" pitch, a .050" gauge, and a total of 114 drive links. Designed with standard chassis and cutter parts, the only distinct feature of this chain is its unique cutter grind.

Please note that the 72RD Chainsaw Chain is specifically designed for use on chain-type sawmills and is not recommended for hand-held applications. Its rugged construction ensures durability and exceptional performance in demanding milling tasks.

One of the standout features of this chain is the innovative LubriLink tie straps. These straps play a crucial role in maintaining optimal lubrication by effectively retaining oil on the chain. This ensures that the chain remains well-oiled, minimizing friction and enhancing its longevity.

In addition, the 72RD Chainsaw Chain boasts a Vibe-Ban chassis design. This design is engineered to significantly reduce vibration, reducing it by an impressive 25% or more at the handles. This reduction in vibration not only enhances comfort during operation but also minimizes user fatigue, allowing for prolonged use without discomfort.

With its top-notch quality and exceptional performance, the 72RD Chainsaw Chain is a must-have tool for professionals in the milling industry. Its reliable construction, combined with the innovative features, ensures an efficient and smooth cutting experience.

Please note that this chain must be used with caution and within its recommended applications. Always prioritize safety by following the manufacturer's guidelines and utilizing appropriate protective gear.

Invest in the 72RD Chainsaw Chain and experience the difference it makes in your milling operations. Its high-quality craftsmanship, enhanced lubrication system, and reduced vibration provide a superior cutting experience, making it an excellent choice for professionals and enthusiasts alike.

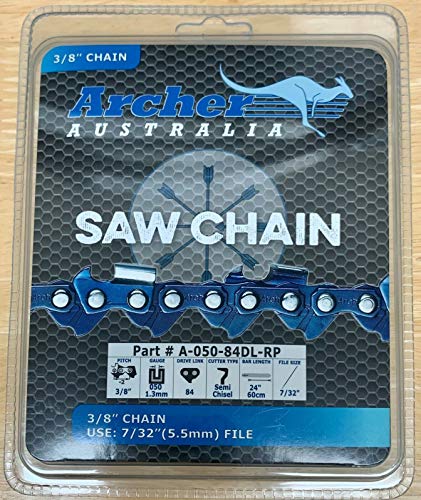

6. 8ten Chainsaw Chain 24" – Husqvarna, Echo, Stihl

The Chainsaw Chain Specs is designed to provide efficient and reliable performance for your chainsaw. With a 24-inch chain length and 84 drive links, this chain is perfect for tackling a variety of cutting tasks. The pitch of the chain is 3/8 inch, while the gauge measures .050 inch, ensuring optimal cutting precision.

This chainsaw chain is specifically designed for ripping, making it ideal for heavy-duty cutting applications. It is important to verify fitment to ensure that this chain is compatible with your machine, so you can enjoy seamless operation and optimal results.

The Chainsaw Chain Specs is a high-quality replacement for OEM part numbers such as Husqvarna 505 02 90-84, 591139484, H51-84, 501 84 25-84, 591119484, H46-84, 501 84 67-84, 591139984, H82-84, 501 84 27-84, H47S-84, 501 84 26-84, and 585550084, C83-84. These compatible part numbers ensure that you are getting a reliable and durable replacement for your chainsaw.

This chainsaw chain is compatible with a range of Husqvarna models, including the 1100, 160, 162, 181, 185, 2100, 2101, 254 (XP), 257, 260, 261, 262 (XP), 266, 268, 272, 281, 285, 288 (XP Lite), 298, 3120 (XP), 355, 357 (XP,XPG), 359 (E-TECH), 360, and 362. It is also compatible with Stihl models such as the 026 (P), 028, 029, 030, 031, 032, 034, 036 (QS), 038, 039, 040, 041, 042, 044, 045, 046, 048, 056, 064, 066, MS 260, MS 261 (C-M,C-MQ,CQ), MS 270 (C,C-B,CQS), MS 290, and MS 291.

Whether you are a professional or a DIY enthusiast, the Chainsaw Chain Specs is a reliable and durable choice for all your cutting needs. With its precise measurements and compatibility with popular chainsaw models, you can trust that this chain will deliver outstanding performance and help you achieve optimal cutting results.

Invest in the Chainsaw Chain Specs today and experience the difference it can make in your cutting tasks. With its high-quality construction and compatibility with various chainsaw models, this chain is a must-have for any chainsaw owner.

Best Ripping Chain For Milling FAQs

Are there any additional accessories or tools necessary when using a ripping chain for milling?

When using a ripping chain for milling, there are a few additional accessories or tools that can enhance the milling process. Although not strictly necessary, these tools can increase efficiency and improve the quality of the final product.

One useful accessory is a chainsaw mill attachment that can be mounted on the chainsaw bar. This attachment acts as a guide, helping to keep the chainsaw aligned and ensuring accurate cuts. It provides stability and allows for more precise milling.

Another accessory that can be helpful is a chainsaw mill rail system. This system consists of rails that are placed parallel to each other, creating a level surface for the chainsaw to ride on. It provides added support and stability, resulting in smoother and more consistent cuts.

Additionally, using a chainsaw sharpener is highly recommended when using a ripping chain for milling. This tool ensures that the chain remains sharp, allowing for efficient cutting and reducing the risk of kickback.

Overall, while these accessories are not essential, they can greatly improve the milling experience and the quality of the finished product.

Are there any differences in the design of ripping chains specifically made for portable chainsaw mills versus larger stationary mills?

Yes, there are some differences in the design of ripping chains made for portable chainsaw mills compared to larger stationary mills.

Firstly, portable chainsaw mills are typically used for smaller-scale milling operations, while larger stationary mills are used for larger logs and higher production. Therefore, the ripping chains for portable mills are generally designed to handle smaller logs and have a narrower cutting width to optimize efficiency and control.

Secondly, the tooth design of ripping chains can vary between portable and stationary mills. Portable chainsaw mill chains may have deeper gullets and more aggressive cutting angles to enhance the cutting performance on smaller logs. This helps to prevent clogging and facilitate faster cutting.

Lastly, the durability and construction of ripping chains can also differ. Chains designed for larger stationary mills are often built with stronger materials and have more robust construction to withstand the higher stress and strain of milling large logs. On the other hand, chains for portable mills may prioritize lightweight design and ease of handling for mobility.

It is important to consider the specific requirements of your milling operation and consult the manufacturer or supplier for their recommendations when choosing a ripping chain for your chainsaw mill.

Are there any specific brands known for producing high-quality ripping chains for milling?

Yes, there are several brands that are known for producing high-quality ripping chains for milling. One popular brand is Oregon, which is widely recognized for its chainsaw accessories and has a range of ripping chains available. Their chains are designed with precision and durability in mind, allowing for efficient and accurate milling. Another reputable brand is Stihl, which is known for its high-performance chainsaws and accessories. They offer ripping chains that are specifically engineered for milling applications, ensuring optimal cutting performance. Additionally, Granberg is a brand that specializes in chainsaw mills and related accessories. They offer ripping chains that are designed to withstand the demands of milling, providing clean and smooth cuts. It is always recommended to research and read reviews before purchasing any chainsaw accessory, including ripping chains, to ensure you are getting a high-quality product that meets your specific needs.

Can a standard chainsaw chain be modified or sharpened to function as a ripping chain for milling?

No, a standard chainsaw chain cannot be modified or sharpened to function as a ripping chain for milling. Ripping chains are specifically designed with different tooth angles and profiles to efficiently cut through wood along the grain. These chains have larger depth gauges and fewer cutting teeth compared to standard chainsaw chains. This design allows them to remove material more aggressively and reduce the strain on the chainsaw motor during the milling process.

If you are planning to mill lumber using a chainsaw, it is highly recommended to invest in a dedicated ripping chain. These chains are readily available in the market and can be purchased to fit your specific chainsaw model. Using the appropriate equipment will ensure safer and more efficient milling operations while producing high-quality results.

How does the gauge of a ripping chain impact its ability to cut through hardwoods during milling?

The gauge of a ripping chain plays a crucial role in its ability to cut through hardwoods during milling. The gauge refers to the thickness of the drive links that are responsible for cutting the wood. A thicker gauge chain is generally more suitable for cutting through hardwoods as it provides greater stability and strength.

When milling hardwoods, the chain is subjected to significant stress and strain due to the density and toughness of the wood. A thicker gauge chain is better equipped to handle this stress and is less prone to bending or breaking. It can maintain its cutting efficiency and accuracy even under challenging conditions.

On the other hand, a thinner gauge chain may struggle when cutting through hardwoods as it lacks the necessary rigidity and durability. It is more likely to deform or snap, compromising the quality of the cut and potentially causing damage to the equipment.

Therefore, when milling hardwoods, it is recommended to use a ripping chain with a thicker gauge to ensure optimal performance, longevity, and safety.

How does the pitch of a ripping chain affect its performance for milling?

The pitch of a ripping chain plays a crucial role in its performance for milling. The pitch refers to the distance between each cutting link on the chain. In general, a larger pitch provides a more aggressive cutting action, making it suitable for milling large logs or hardwoods. On the other hand, a smaller pitch offers a smoother and more precise cut, making it ideal for milling smaller logs or softer woods.

When it comes to milling, the choice of pitch depends on various factors such as the size and type of the logs, the desired finish, and the power of the milling equipment. For instance, if you are working with larger logs and require faster cutting, a larger pitch like 3/8" or 0.404" might be suitable. Conversely, if you are milling smaller logs or aiming for a smoother finish, a smaller pitch like 0.325" or 0.375" could be more appropriate.

Ultimately, the selection of the pitch for a ripping chain should be based on the specific milling requirements and the capabilities of the milling equipment being used. It is always recommended to consult the manufacturer's guidelines or seek advice from experienced millers to ensure optimal performance.

What are some common issues or challenges that users may face when using a ripping chain for milling, and how can they be overcome?

When using a ripping chain for milling, users may encounter a few common issues or challenges. One such issue is the chain getting stuck or binding in the wood. This can happen if the chain is not properly sharpened or if the depth gauge settings are incorrect. To overcome this, it is important to ensure that the chain is sharpened regularly and that the depth gauge settings are properly adjusted according to the type of wood being milled.

Another challenge users may face is the chain getting dull quickly. This can happen if the chain is not properly lubricated or if it comes into contact with abrasive materials. To overcome this, users should ensure that the chain is properly lubricated before each use and that it is not used on materials that can quickly dull the teeth.

Additionally, users may also face challenges related to the size of the wood being milled. If the wood is too large or uneven, it may cause the chain to become unstable or create an uneven cut. In such cases, it is advisable to properly secure the wood and make sure it is of suitable size and shape for milling.

Overall, by regularly maintaining and sharpening the chain, ensuring proper lubrication, and working with appropriately sized wood, users can overcome these common challenges when using a ripping chain for milling.

What are the key features to look for when choosing a ripping chain for milling purposes?

When choosing a ripping chain for milling purposes, there are several key features to consider. Firstly, you should look for a chain with a high cutting efficiency. This means the chain should have sharp and durable cutting teeth that can effectively remove material during the milling process.

Secondly, the chain should have a proper tooth configuration for ripping. Ripping chains typically have larger, more aggressive cutting teeth compared to standard chains. These teeth are designed to efficiently cut along the grain of the wood, allowing for smoother and faster milling.

Additionally, it is important to choose a ripping chain that is compatible with your milling equipment. Check the specifications of your mill to ensure that the chain you choose will fit and work properly with your setup.

Lastly, consider the durability and longevity of the chain. Look for chains made from high-quality materials that can withstand the demands of milling. Chains with features like chrome-plated cutters or hardened steel construction tend to offer better durability and longer lifespan.

Overall, the key features to look for when choosing a ripping chain for milling purposes include cutting efficiency, proper tooth configuration, compatibility with your equipment, and durability. By considering these factors, you can select a chain that will optimize your milling operations.

What is the best ripping chain for milling large logs?

When it comes to milling large logs, the choice of a ripping chain is crucial for achieving optimal results. One of the highly recommended options for milling large logs is the Oregon 72RD072G ripping chain. This chain is specifically designed for professional use and excels in cutting efficiency and durability.

The Oregon 72RD072G features a large cutting tooth that helps to remove material quickly and effectively, making it ideal for milling large logs. Its aggressive cutting performance allows for smooth and precise cuts, resulting in high-quality lumber. Additionally, the chain's durability ensures it can withstand the demanding conditions of milling without losing its sharpness or strength.

However, it is important to note that the choice of a ripping chain also depends on the type of mill, the size and hardness of the logs, and personal preferences. Consulting with experienced millers or professionals in the field can provide valuable insights and help you make an informed decision based on your specific milling needs.

What is the optimal cutting angle for a ripping chain when used for milling purposes?

The optimal cutting angle for a ripping chain when used for milling purposes is typically around 10 degrees. This angle allows for efficient and smooth cutting through the wood fibers, maximizing the cutting performance and minimizing the strain on the chain and the milling equipment.

However, it's important to note that the optimal cutting angle may vary depending on factors such as the type of wood being milled and the specific milling equipment being used. It is recommended to consult the manufacturer's guidelines or seek advice from experienced professionals in the field to determine the most suitable cutting angle for your specific milling needs.

Additionally, regular maintenance and sharpening of the chain are crucial to ensure optimal cutting performance. Keeping the chain properly tensioned and sharpened will help maintain the desired cutting angle and extend the lifespan of the chain.