If you’re looking for a high-quality grinder for knife making, then look no further. A grinder is an essential tool for knife making, and it’s important to invest in a good one. But with so many options available, it can be difficult to know where to start. In this article, we’ll discuss some factors you should consider before making a purchase.

Firstly, think about the power of the grinder you need. How much horsepower do you require for your projects? You don’t want to invest in a grinder that’s too powerful or not powerful enough for your needs. Secondly, consider the size of the wheel you want. A larger wheel will reduce the time it takes to grind metal, but it may also increase the cost. Finally, consider the durability of the grinder. It’s essential to invest in a grinder that’s built to last and can withstand daily use.

Are you tired of using low-quality tools that just don’t cut it? Do you want to take your knife making to the next level? A good grinder can make all the difference when it comes to creating high-quality knives. But with so many options on the market, it can be tough to know where to start. That’s why we’ve put together this article to help you make an informed decision. Keep reading for some helpful tips and questions to ask yourself before making a purchase.

10 Best Grinder For Knife Making

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

Ideal for knife making with its belt grinder, disc sander, grinding wheel, bench sander, wheel and platen tool rest.

|

|

||

|

2

|

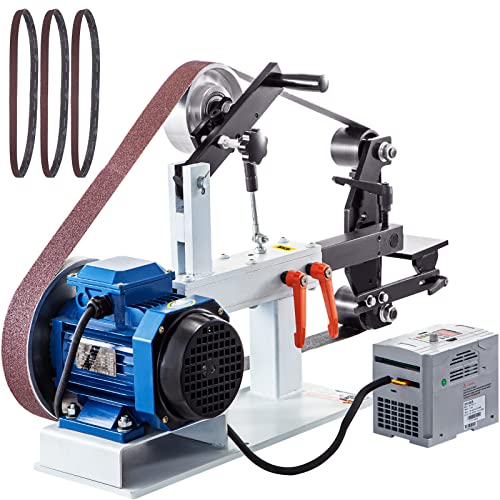

This product, a belt grinder with variable speed and various attachments, is ideal for knife making and precise metal grinding.

|

|

||

|

3

|

Ideal for woodworking and metalworking, with variable speed electric belt sander, sanding belt papers, and grinding wheel.

|

|

||

|

4

|

It is ideal for knife making and sanding tasks with its 2-inch belt grinder and 6-inch disc bench sander.

|

|

||

|

5

|

Ideal for grinding, sharpening and sanding tasks with a large work table and upgraded model features.

|

|

||

|

6

|

This product is ideal for DIY wood working and knife making, offering a powerful and versatile sanding and polishing machine.

|

|

||

|

7

|

Ideal for sharpening and grinding knives, with adjustable bevel angles, making it suitable for professional use.

|

|

||

|

8

|

It is ideal for knife sharpening and making using a belt sander machine.

|

|

||

|

9

|

This product is ideal for accurately sharpening knives at customizable angles using a belt sander machine.

|

|

||

|

10

|

Ideal for knife making with a constant speed 2×82 inch belt disc sander, 3 grinding wheels, and bench sander.

|

|

1. Vevor 2hp Belt Grinder: Ultimate Knife Making Tool.

The 3-in-1 Belt Grinder is a powerful and versatile tool that can cater to all your grinding needs. Equipped with a high-quality abrasive belt and durable wheels, this belt sander features a non-slip design and a fast grinding speed. It offers three different types of grinding – circular, arc, and flat grinding, allowing you to choose the most suitable type as per your requirement.

The powerful 1500W copper motor of this belt sander runs smoothly and produces low noise, ensuring stable tracking. With a rotating speed of 0-2800 RPM, you can achieve precise and efficient grinding results. The all-steel construction of this commercial belt sander makes it durable and long-lasting. The all-steel frame is welded at all joints, providing a solid structure. The thickened square base ensures smooth working, making it perfect for use in parts factories, building materials factories, and other similar places.

This bench belt sander can be used for grinding various materials like metals, wood, acrylic, and more. The belt size of 2" x 82" is easy to change and adjust with a belt adjustment handle. Additionally, the three different wheels are easy to disassemble and assemble. The worktable angle can be adjusted, allowing you to work at the most suitable angle for your needs.

Overall, the 3-in-1 Belt Grinder is a reliable and efficient tool that can cater to all your grinding needs with ease.

- High-quality abrasive belt with durable wheels

- Three grinding types – circular, arc, and flat grinding

- Powerful 1500W copper motor with rotating speed of 0-2800 RPM

- All-steel construction for durability and stability

- Suitable for grinding various materials

- Easy to change and adjust belt with a belt adjustment handle

- Adjustable worktable angle

2. Variable Speed Belt Sander For Knife Making

Upgrade your grinding game with the 3-in-1 Belt Grinder. This machine features a high-quality abrasive belt with durable wheels, designed with a non-slip feature and a fast grinding speed. You can choose from three grinding options such as circular grinding, arc grinding, or flat grinding, depending on your needs. With a powerful 1500W motor, this sander works well with a high-speed, low-noise copper motor, allowing for smooth operation and stable tracking. The speed of the belt can be adjusted from 0-2800 RPM to fit your grinding requirements. The all-steel construction of this commercial belt sander makes it durable and stable, built to last. The thickened square base ensures smooth working and the all-steel frame is welded at all joints, making it solid enough to handle any grinding job. This bench belt sander can be used for grinding metals, wood, acrylic, and other materials, making it perfect for tool polishing. The belt size of 2" x 82"/5.08 x 208.28 cm is easy to adjust and change with a belt adjustment handle. Additionally, the three different wheels are also detachable and easy to assemble. With the included frequency converter, you can convert the speed from 1 phase into 3 phases, making it easy to operate and adjust the speed of the machine.

- Three grinding options available for various grinding needs

- Powerful 1500W motor for smooth operation and stable tracking

- Adjustable belt speed from 0-2800 RPM for precise grinding

- All-steel construction makes it durable and stable

- Easy to operate and adjust the speed with a frequency converter

- Detachable wheels and easy to assemble

- Suitable for grinding metals, wood, acrylic, and other materials

- Thickened square base ensures smooth working

3. Diyarea Electric Belt Sander – Precision Woodworking & Metalworking.

The DIYAREA electric belt sander is a heavy-duty and durable tool that comes equipped with a powerful 1.5 KW motor. This premium pure copper motor is speed adjustable and runs smoothly, ensuring precise and stable tracking. With a maximum rotating speed of 0-2800 RPM, it is perfect for grinding wood, metals, acrylic, and other materials.

This commercial belt sanding machine features an all-steel construction that is solidly welded for added strength and stability. The thickened square base has 2 holes for bolt fastening, ensuring a smooth working experience. It also comes with three grinding molds, including circular grinding, arc grinding, and flat grinding, allowing users to choose the appropriate type for their needs.

The DIYAREA electric belt sander is easy to use and comes with 3 2" x 82" sander papers. It is easy to adjust the handle and hydraulics to make it suitable for 2" x 72" sander papers use. The three molds are also easy to install and disassemble. The VFD parameter is set at the factory, allowing users to use it directly.

Overall, this bench belt sander is widely used in parts factories, woodworking factories, building materials factories, and other industries, making it perfect for tool polishing and grinding tasks.

- Powerful 1.5 KW motor with a maximum rotating speed of 0-2800 RPM

- All-steel construction with solid welding for added strength and stability

- Comes with three grinding molds for added versatility

- Easy to use and adjust for different paper sizes

- Widely used in various industries

4. Knife Maker's Dream: 2-In-1 Belt And Disc Sander

Get ready to experience high-efficiency grinding with this sand belt and sand disc integrated machine. With a rotating speed of 3450 rpm/min, disc speed of 35m/s and belt speed of 18m/s, this machine guarantees quick and smooth sanding. The sturdy structure of this machine is designed to prevent wobbling and walking during operation. It comes with a preset 6" disc with 60 mesh and a 2" belt with 80 mesh.

The sanding belt and disc are replaceable, making it easy for you to switch between different materials. The angle of the belt holder is adjustable from 0-90°, providing you with high flexibility during operation. The machine comes equipped with a protective eye guard that prevents sparks and debris from entering your eyes, and an LED working lamp that illuminates the working space and details. The detachable sink ensures that the grinder materials remain cool during operation.

This sanding disc and belt machine is suitable for a wide range of applications including mirror finish, grinding, and polishing of wood, plastic, metal, and other materials. It is a perfect tool for professionals and DIY enthusiasts alike.

- High-efficiency sanding with a rotating speed of 3450 rpm/min

- Sturdy structure prevents wobbling and walking during operation

- Adjustable belt holder angle for high flexibility

- Protective eye guard and LED working lamp for safety

- Detachable sink for cooling of grinder materials

- Suitable for a wide range of applications including mirror finish, grinding, and polishing

5. Bucktool Combo Workstation: Sharpener, Sander, Grinder.

The heavy-duty construction of this sander ensures a long-lasting lifespan while meeting the CSA standards. It operates on a 1/3HP, 3.5 Amp induction motor that provides the necessary power even under load. The no-load wheel speed is 3450 RPM and the belt speed is 4480 FPM. This multi-functional sander includes a 2-Inch x 42-Inch high-quality metal sanding belt that can be used on various materials such as metals, wood, plastics, and more for general purpose sanding and finishing. The belt can be tilted from 0 to 90 degrees for multi-angle sanding and the belt housing can swivel from horizontal to vertical for sanding long workpieces. The 6-Inch 60 grit white grinding wheel with tool-free adjustable eye shield and LED light makes it easy to use, and the quick-release tension and tracking mechanism allows for quick and easy belt changes. This sander also comes with two workbenches to enhance convenience – the cast iron belt sander work table provides better support when sharpening with metal, and the cast AL big work table is ideal for wood materials. The sturdy cast iron base with rubber foot prevents vibrations, ensuring stability during operation.

- Heavy-duty construction for long-lasting lifespan

- Meets CSA standards

- 1/3HP, 3.5 Amp induction motor provides necessary power even under load

- Multi-functional sander for various materials

- Multi-angle sanding with adjustable belt and housing

- Easy to use with tool-free adjustable eye shield and LED light

- Quick-release tension and tracking mechanism for easy belt changes

- Two workbenches for enhanced convenience

- Sturdy cast iron base with rubber foot prevents vibrations for stability during operation

6. Apex Mini Grinder: Ultimate Diy Sharpening Tool

The Mini Belt Sander Machine is a powerful tool that comes with a super strong motor, making it ideal for grinding metals, wood, acrylic, and other materials. Its 7 adjustable speed grinder polisher allows for a no-load speed of 4500-9000RPM, ensuring fast and efficient sanding.

The workbench angle of this belt sander can be adjusted to suit your preferences. With its humanized design structure, the sander is super stable and will not move during working. It features a built-in double bearing that is non-slip, preventing dust from entering the machine and damaging the bearing.

This Mini Electric Sander is small and delicate, making it perfect for small workshop and intricate work. It comes with a tiny size belt sander that is great for sanding in tight spaces. The belt size is 12.9 x 0.35 in and the machine size is 5.9 x 3.93 x 5.51 in.

The belt sander has a special noise reduction design that ensures a noise level of just 30 db, protecting the ears of operators and people in the surrounding area.

Overall, this Mini Belt Sander Machine Mini Electric Sander is a great tool that features a humanized design structure, a powerful motor, and adjustable workbench angle. It is perfect for sanding small spaces and delicate work while ensuring low noise and high efficiency.

- Powerful motor for efficient sanding

- Adjustable workbench angle for comfortable use

- Small and delicate, perfect for small workshop and intricate work

- Special noise reduction design for low noise operation

- Built-in double bearing, non-slip, and dustproof for added durability

7. Prosharp Belt Grinder – Professional Knife Grinding

Knife making is an ancient craft that has evolved into a supreme art form over time. While earlier man used sharpened stones for the job, today's knife making demands precision and consistency. This is where the KNIPEX Belt Grinder for Knife Making comes in.

Designed for grinding bevel angles on a knife blade and blank grinding, this grinder angle is an excellent tool for knife makers. With its belt grinder jig, it relieves strain from the hands and improves grinding precision. It also features a polished bottom that slides smoothly on the working table.

The KNIPEX Belt Grinder is particularly useful for removing unwanted paint or residue on a surface without damaging it. This belt knife grinder can maintain the finish of the surface while getting rid of the residue.

Using the KNIPEX Belt Grinder for Knife Making is easy and efficient. With minimal effort on your part, you can shape and smooth the surface of your knives to perfection. However, caution should be exercised to avoid tilts and use minimum pressure.

Overall, the KNIPEX Belt Grinder for Knife Making is an excellent tool for knife makers who are looking for a quicker and more efficient way to remove material and shape material surfaces. It is an electric knife grinder that is easy to use and gives your materials the finishing touch you have been looking for.

- Designed for grinding bevel angles on a knife blade and blank grinding

- Features a belt grinder jig that relieves strain from the hands and improves grinding precision

- Polished bottom that slides smoothly on the working table

- Can remove unwanted paint or residue from a surface without damaging it

- Easy to use and efficient

- Quicker and more efficient way to remove material and shape material surfaces

- – Caution must be exercised to avoid tilts and use minimum pressure

8. Belt Knife Sharpener Jig With Dual Handles

The grinding jig is an excellent processing assistant tool that is built to last due to its durable aluminum alloy frame. The precise scale plate is made of high-quality stainless steel, which ensures high accuracy and longevity for multiple uses. The grinder knife sharpener measures 7-3/4'' in length, 3-9/10'' in width, 3-2/5'' in height and comes with a locking knob and ultra-fine thread turnbuckle for more precise adjustments from 85 to 115 degrees.

The double ergonomic handles and tool holder make the grinding jig comfortable and convenient to use. The knurled surface of the two aluminum handles provides a superior feel and secure grip, while the ABS plate at the bottom reduces friction and unnecessary wear during use.

This knife sharpening jig is easy to use and comes with a set of stainless steel screws for easy grinding of any size knife. It is ideal for knife-making and is compatible with most sander machines, belt machines, etc. With its easy-to-use features and strong practicality, this knife sharpening jig can easily satisfy your varied demands.

- Durable aluminum alloy frame for long-term use

- High-quality stainless steel scale plate for high accuracy

- Double ergonomic handles and tool holder enhance comfort during use

- Adjustable angle from 85 to 115 degrees with locking knob and ultra-fine thread turnbuckle

- Easy to use with set of stainless steel screws for easy grinding of any size knife

- Compatible with most sander machines, belt machines, etc.

9. Precision Pro Knife Grinder Jig

The grinding jig is an excellent processing assistant tool that is built to last. Its aluminum alloy frame ensures durability and longevity for multiple uses, while the precise scale plate is made of quality stainless steel, providing high accuracy. The grinder knife sharpener measures 7.75'' in length, 3.9'' in width, and 3.4'' in height, making it a perfect fit for most sander machines, belt machines, etc.

The grinding jig features a flexible angle with a locking knob and ultra-fine thread turnbuckle for more precise adjustments from 85 to 115 degrees. It also comes with a set of stainless steel screws for easy grinding of any size knife, and an ABS plate at the bottom that can slide flexibly in use to reduce friction and unnecessary wear.

The double ergonomic handles of the grinding jig are accessible operation properties that enhance comfort during use. These two aluminum handles have a knurled surface and are designed for superior feel and secure grip. With the advantages of easy use and strong practicality, this knife sharpening jig can satisfy your different demands and efficiently make knives.

- Durable and long-lasting aluminum alloy construction

- Precise scale plate made of quality stainless steel for high accuracy

- Flexible angle with a locking knob and ultra-fine thread turnbuckle for precise adjustments

- Comes with a set of stainless steel screws for easy grinding of any size knife

- Double ergonomic handles with a knurled surface for superior feel and secure grip

- Ideal for knife making and fits most sander machines, belt machines, etc.

- Includes an ABS plate at the bottom that can slide flexibly in use to reduce friction and unnecessary wear

- Easy to use and strong practicality

10. Happybuy Belt Disc Sander With Grinding Wheel.

The high-quality abrasive belt of this belt sander is designed with durable wheels, featuring a non-slip design that allows for fast grinding speed and efficient use of time and effort. It comes with three different grinding wheels and three extra abrasive belts to enhance its versatility.

Built with an all-steel construction, this commercial belt sander is designed to last. Its sturdy base and easy-to-maintain structure make it a great investment for long-term use.

Equipped with a high-speed pure copper motor that runs smoothly and boasts stable tracking, this power sander is capable of reaching a rotating speed of 2800r/min. Despite its powerful performance, this machine is relatively quiet during operation.

With a belt size of 2" X 82", this belt sander is easy to operate and adjust via its belt adjustment handle. Its three different wheels are also easy to disassemble and assemble, making it a convenient tool for your work. The speed is fixed for constant performance.

Ideal for grinding metals, wood, acrylic, and other materials, this bench belt sander is suitable for use in parts factories, building materials factories, and other similar settings. It is the perfect tool for polishing various tools.

- Designed with high-quality abrasive belts and durable wheels for efficient and fast grinding

- All-steel construction ensures durability and stability

- High-speed pure copper motor runs smoothly and quietly with stable tracking

- Easy to operate and adjust with a belt adjustment handle and three different wheels

- Versatile tool suitable for grinding various materials and widely used in parts factories and building materials factories

Best Grinder For Knife Making FAQs

How does the cost of a grinder for knife making impact its performance and durability?

The cost of a grinder for knife making can have a significant impact on its performance and durability. Higher-end grinders typically have more powerful motors, more durable components, and better precision, which can result in more consistent and efficient grinding of knives. These grinders are also usually made with higher-quality materials, such as stainless steel or aluminum, which can withstand the wear and tear of frequent use.

On the other hand, cheaper grinders may have less powerful motors, lower-quality components, and looser tolerances, which can result in less consistent and less efficient grinding. These grinders may also be made with cheaper materials, such as plastic or lower-grade metals, which can wear out more quickly and require more frequent replacement.

Ultimately, the cost of a grinder for knife making will depend on the individual's needs and budget. However, it is important to keep in mind that investing in a higher-quality grinder can lead to better performance and durability over the long term.

How does the type of grinding wheel impact the quality of the finished knife?

The type of grinding wheel used in knife making is an important factor that directly impacts the quality of the finished knife. There are different types of grinding wheels available such as diamond, ceramic, aluminum oxide, and silicon carbide. Each type of wheel has its unique characteristics that affect the outcome of the sharpening process.

Diamond grinding wheels are known for their durability and precision. They are ideal for sharpening high-end knives and producing a fine edge. Ceramic wheels, on the other hand, are softer and less aggressive than diamond wheels. They are ideal for removing metal from the blade and creating a smooth finish.

Aluminum oxide and silicon carbide wheels are commonly used in general purpose knife sharpening. They are affordable and readily available. However, they are not as durable as diamond or ceramic wheels, and they tend to wear out quickly.

In conclusion, the type of grinding wheel used in knife making plays a significant role in the quality of the finished knife. It is essential to choose the right type of wheel for the specific task at hand to ensure optimal results. A high-quality grinding wheel, used correctly, can enhance the performance of the knife and improve its overall longevity.

What are some common mistakes to avoid when using a grinder for knife making?

When it comes to knife making, using a grinder is an important step to shape and sharpen the blade. However, there are some common mistakes that beginners should avoid to ensure a successful outcome.

One mistake to avoid is applying too much pressure to the grinder. This can cause the blade to overheat and lose its temper, making it less durable and potentially dangerous to use. It’s important to let the grinder do the work and apply just enough pressure to guide the blade.

Another mistake is not using the proper safety equipment. A grinder can produce a lot of sparks and debris that can cause eye and skin damage. It’s important to wear safety goggles, gloves, and a dust mask to protect yourself.

Finally, not taking breaks during the grinding process can lead to fatigue and mistakes. It’s important to take breaks and step away from the grinder to prevent mistakes and ensure that you are working safely.

By avoiding these common mistakes and taking the time to learn proper techniques, you can successfully use a grinder for knife making and create high-quality blades.

What are the key features to look for when selecting a grinder for knife making?

When selecting a grinder for knife making, there are several key features that you should consider. First and foremost, you need to look for a grinder that has a powerful motor. This will ensure that you can grind even the toughest materials with ease. Additionally, you should look for a grinder that has a large wheel diameter. This will make it easier to grind longer knives and will also help to reduce the wear and tear on the wheel.

Another important feature to consider is the speed of the grinder. A faster speed will help you to get the job done more quickly, but you need to be careful not to overheat your blades. You should also look for a grinder that has a sturdy base and a solid construction. This will ensure that the grinder stays in place while you are working and will prevent it from vibrating or wobbling.

Finally, you should consider the type of grinding wheel that the grinder uses. There are a variety of different types of grinding wheels available, including diamond, ceramic, and aluminum oxide. Each type of wheel has its own unique benefits and drawbacks, so you should choose the one that best meets your needs. Overall, by considering these key features, you can find the perfect grinder for all of your knife making needs.

What is the optimal grinding speed for creating a high-quality edge on a knife?

The optimal grinding speed for creating a high-quality edge on a knife depends on various factors, such as the type of knife, the material it is made of, and the desired sharpness level. Generally, a grinding speed between 1200-1800 RPM is considered ideal for most knife sharpening tasks. However, it is crucial to maintain a consistent speed throughout the process to avoid overheating the blade or causing excessive wear on the grinding wheels.

It is also important to note that the grinding angle and pressure applied during sharpening can significantly impact the final sharpness of the blade. A lower grinding angle and lighter pressure are generally recommended for achieving a sharper edge, while a higher angle and heavier pressure may be more suitable for durability and heavy-duty tasks.

Ultimately, the optimal grinding speed for creating a high-quality edge on a knife depends on the specific requirements and preferences of the user. It is essential to experiment with different techniques and tools to find the best approach for achieving the desired results.