If you’re looking for a way to install engineered hardwood flooring over a concrete subfloor, using the right glue is essential. Not only will it ensure that your floor stays in place, but it can also help to reduce noise and provide a stable surface for walking and furniture placement. In this article, we’ll discuss some of the factors you should consider before purchasing glue for engineered hardwood on concrete.

Firstly, make sure that you have the correct subfloor for your installation. Concrete subfloors should be clean, dry, and level before installing any type of flooring. It’s recommended to use a moisture barrier over concrete subfloors, particularly in areas where moisture levels are high or in basements. You’ll also need to select a glue that’s appropriate for the type of wood you’re installing and the climate you’re in.

When considering which glue to purchase, keep in mind factors such as setting time, cleanup, and ease of application. Some glues require more preparation or specialized equipment to apply, while others offer quick drying and easy clean-up. You should also take into account the cost per square foot of the glue, as some types can be more expensive than others.

Are you struggling to choose the right glue for your engineered hardwood flooring installation? Do you have questions about the compatibility of the glue with your specific wood and subfloor? Keep reading for our top recommendations and answers to frequently asked questions about glue for engineered hardwood on concrete installations.

10 Best Glue For Engineered Hardwood On Concrete

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for installing engineered wood flooring.

|

|

||

|

2

|

This product is ideal for priming flooring adhesive and ensuring a strong bond between the floor and adhesive.

|

|

||

|

3

|

Ideal for repairing wood damage, filling gaps and cracks, bonding wood surfaces, and quick-setting high-strength applications.

|

|

||

|

4

|

The product is ideal for bonding various types of flooring materials to a subfloor.

|

|

||

|

5

|

Ideal for edging and refinishing hardwood floors in residential or commercial environments.

|

|

||

|

6

|

This product is ideal for adding storage and style to your living space through its hidden storage feature and modern design.

|

|

||

|

7

|

Ideal for installing engineered hardwood flooring quickly and with precision using a stapling method.

|

|

||

|

8

|

The product is ideal for bonding wood, stone, laminate, and rubber floors indoors and outdoors using a moisture-curing polyurethane adhesive.

|

|

||

|

9

|

Ideal for providing slip-resistant and protective surfaces on various indoor and outdoor flooring.

|

|

||

|

10

|

This product is ideal for bonding wood surfaces together.

|

|

1. Roberts 1407-1 Engineered Wood Flooring Adhesive, 1 Gallon , Beige

The flooring adhesive is designed for engineered wood planks, plain back parquet flooring, and acrylic-impregnated planks that are up to 1/2 in. thick and 5 in. wide. It can bond with APA rated plywood, acoustic cork underlayment, and concrete, both on and above grade. The adhesive is perfect for direct bond installations and is suitable for heavy residential and moderate commercial traffic. Its open time is around 20 minutes, while the working time is 30 minutes. The curing time is between 24 to 48 hours. The adhesive can cover approximately 45 to 55 and 70 to 80 sq. ft. per gallon for engineered wood and prefinished parquet flooring installations, respectively. It is recommended to use with a 1/4 in. x 1/4 in. x 1/4 in. V-notch trowel or 1/8 in. x 1/8 in. x 1/8 in. square notch trowel, depending on the type of installation. The adhesive is solvent-free and LEED compliant, and its VOC content is less than 2 g/L according to SCAQMD Rule 1168. It is non-flammable, making it safe to use.

- Suitable for various types of planks and flooring

- Can bond with APA rated plywood, acoustic cork underlayment, and concrete

- Perfect for direct bond installations

- Suitable for heavy residential and moderate commercial traffic

- Solvent-free and LEED compliant

- Non-flammable for safe use

2. Roberts 1406-P Flooring-Adhesive-Primers, 1 Pint Bottle, White

This adhesive is specially designed for floated engineered wood and laminate flooring installations. It offers a strong and long-lasting bond that ensures your flooring stays in place for years to come. The water-based formula is zero VOC calculated, making it an eco-friendly choice. Additionally, it is non-flammable and non-toxic, making it safe to use in any environment. Its water-resistant properties make it ideal for areas that may be exposed to water or moisture. The adhesive is completely odorless, ensuring that there is no unpleasant smell during or after installation. Furthermore, the quick flip-top applicator lid makes it easy to apply the adhesive quickly and accurately.

Overall, this adhesive provides a reliable and durable solution for your flooring installation needs. Its eco-friendly and safe properties make it an excellent choice for any home or professional project.

- Provides a strong and long-lasting bond

- Zero VOC calculated, non-flammable and non-toxic formula

- Water-resistant properties make it ideal for areas exposed to water or moisture

- Odorless

- Quick and easy to apply with the flip-top applicator lid

3. Dritac Professional Wood Repair Adhesive 1 Gallon

Say goodbye to the annoying hollow spots and popping sounds on your engineered wood flooring installations with DriTac Repair Adhesive RS-8. This innovative repair system is specifically designed to address these common issues, ensuring that your floor is sturdy, safe, and enjoyable to walk on.

DriTac Repair Adhesive RS-8 comes in a one US gallon container, providing ample amount of adhesive for your flooring needs. Its advanced formula effectively fixes hollow spots and popping conditions on engineered wood floors, restoring their stability and durability. The adhesive works by penetrating through the voids and gaps in the floor, creating a strong and permanent bond that eliminates the annoying noises and hollow sounds that often plague these types of floors.

Aside from its excellent adhesive properties, DriTac Repair Adhesive RS-8 is also easy to use. Simply spread the adhesive on the affected area using a trowel or putty knife, and let it dry for 24 hours. Once dry, your engineered wood floor will be as good as new, with no more hollow spots or popping sounds to worry about.

If you're looking for a reliable and effective solution to fix hollow spots and popping conditions on your engineered wood flooring, DriTac Repair Adhesive RS-8 is definitely worth considering. It's easy to use, provides ample coverage, and delivers long-lasting results that you can count on.

- Effectively fixes hollow spots and popping conditions on engineered wood floors

- Creates a strong and permanent bond

- Easy to use

- One US gallon container provides ample coverage

- Delivers long-lasting results

- – May not be suitable for other types of flooring

- – Requires 24 hours of drying time

4. Dap 142 00142 Weldwood Multi-Purpose Floor Adhesive, Gallon, White

The Model number 142 adhesive is a highly effective solution for various installation needs. It has a unique formula that provides greater shrink resistance, making it ideal for various applications. Additionally, it is designed to allow for easy repositioning during installation, ensuring that your project is completed with precision and accuracy. This adhesive is also highly water-resistant, which makes it suitable for use in damp or humid environments.

One of the most significant advantages of this adhesive is its low odor and low VOC properties, making it safe for use in enclosed spaces. It is also nonflammable, which is an added safety feature. Another great feature of this adhesive is its easy water clean-up, making it easy to clean up any spills or excess adhesive quickly and efficiently.

The Model number 142 adhesive is a highly versatile and reliable adhesive that can be used in various applications. Whether you are working on a DIY project or a professional installation, this adhesive is a must-have for anyone looking for a reliable and effective solution.

- Provides greater shrink resistance

- Allows for easy repositioning during installation

- Water-resistant

- Low odor and low VOC properties

- Nonflammable

- Easy water clean-up

- Highly versatile and reliable

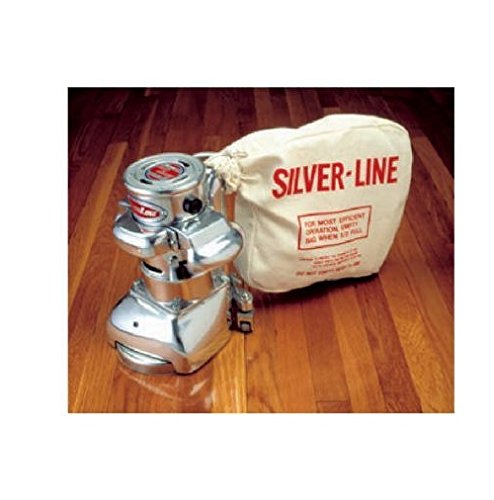

5. Essex Sl-7 Silver Line Floor Edger

Introducing the innovative dustless edger, perfect for your sanding needs. This edger is designed with an oversized vacuum and chamber that enables it to collect dust effectively, keeping your workplace clean and dust-free. Its nylon bar glides along the floor smoothly, eliminating wheel marks to give you a seamless finish. This edger is specially designed without a caster, so it can be used on softwoods without leaving any marks.

With this dustless edger, you can achieve a professional-looking finish easily and efficiently. The vacuum and chamber work together to eliminate dust, reducing the risk of respiratory problems and keeping your workspace clean. The nylon bar allows for smooth and easy sanding, without leaving any marks or scratches on your floor. You can use this edger confidently on softwoods, without worrying about any damage.

Overall, this dustless edger is a must-have tool for anyone looking to achieve a professional-looking finish. Its efficient dust collection system and smooth gliding bar make it easy to use and maintain, while its design allows for safe use on softwoods.

- Efficient dust collection system

- Smooth gliding bar for easy sanding

- Safe to use on softwoods

6. Waveform Lift Top Coffee Table With Hidden Storage

The unique and elegant fluted panel design of this coffee table is fabricated through a special technology. The streamlined frame features rounded corners, making it safe for little ones. The lift top design is equipped with a high-quality spring mechanism, allowing the tabletop to be lifted or lowered down easily, smoothly, and quietly. This turns the coffee table into a workbench or dining space when sitting on the sofa. The box frame leg is designed to distribute the weight equally across all four legs, so you don't have to worry about uneven legs. The coffee table also has two hidden compartments beneath the tabletop, providing space for storing your often-used items like magazines, laptop, remote controllers, and game controllers, keeping them handy. The coffee table measures 35.5 x 19.8 x 16.5 inches and comes with a 30-day return policy and a 1-year warranty. Please note that there may be a color variance between the actual product and the photos due to different lighting conditions and online viewing device settings.

- Unique and elegant fluted panel design

- Streamlined frame with rounded corners for safety

- Lift top design with a high-quality spring mechanism

- Box frame leg distributes weight equally across all four legs

- Two hidden compartments beneath the tabletop for storage

- Comes with a 30-day return policy and a 1-year warranty

- – Color variance between the actual product and photos due to different lighting conditions and online viewing device settings

7. Bostitch Flooring Stapler For Engineered Hardwood (Ehf1838k) , Black

The adjustable knobs of this flooring nailer make it easy to adjust the depth settings without the need for any tools. It can handle solid hardwood of 5/16 to 7/16 inches and engineered hardwood and bamboo of 1/2 to 5/8 inches. The over-molded rubber grip ensures a comfortable grip and maneuverability. The muffled rear exhaust directs air away from the workspace, reducing noise levels. The non-marring trip tips protect the flooring from accidental damage. Additionally, it has an easy sight tongue engagement that ensures you hit the pocket every time with precision.

- Adjustable knobs allow for tool-free depth adjustment

- Over-molded rubber grip provides comfort and maneuverability

- Muffled rear exhaust directs air away from workspace

- Non-marring trip tips prevent accidental damage to flooring

- Easy sight tongue engagement ensures precise placement

8. Stablebond Rubber Floor Adhesive – 4 Gallons

Looking for a reliable adhesive to lock in your new indoor and outdoor flooring projects? Look no further than this solvent-free polyurethane formula from IncStores. With enhanced protection against water, weather, weight, and wear, this adhesive is perfect for all types of flooring, including rubber, stone, cork, laminate, hardwood floors, and more.

Not only is this urethane floor glue suitable for a range of flooring materials, but it can also be used for stair treads, radiant heating systems, transition strips, and subfloors, thanks to its versatile all-purpose elastomeric formula. Whether you're a homeowner or a business owner, you can count on this commercial-grade adhesive to provide the heavy-duty bond you need for large spaces.

With every bucket covering up to 360 sq. ft. of flooring, stair tread, or underlayment, this urethane adhesive finish offers exceptional coverage for any project. Plus, it's designed to withstand the freezing and thawing of your space throughout the seasons, providing reliable protection against the elements.

For over a decade, IncStores has been committed to providing high-quality rubber flooring products in countless styles. This urethane adhesive is no exception, offering a foundation of quality you can trust to keep your floors secure and looking great.

- Suitable for a range of flooring materials, including rubber, stone, cork, laminate, and hardwood floors

- Versatile all-purpose elastomeric formula can be used for stair treads, radiant heating systems, transition strips, and subfloors

- Commercial-grade adhesive provides heavy-duty bond for large spaces

- Covers up to 360 sq. ft. of flooring, stair tread, or underlayment per bucket

- Designed to withstand the freezing and thawing of your space throughout the seasons

- Solvent-free formula is environmentally friendly

9. Et Multi Color Rubber Backing, 1 Gal

Keep your area rugs from slipping and sliding with Fiber-Lok Non-skid Rug Backing. This innovative formula offers a simple solution to the problem of unstable carpets, while also leaving no stains on your floors. The air-drying anti-skid formula is easy to apply and machine washable, so you can be sure your rugs will stay in place even after washing.

To apply, simply brush a thin, even coat of the backing onto the backside of your rug. The transparent coating will dry completely, leaving your rug with a crystal clear finish that won't wear off. This 32-ounce bottle covers up to 30 square feet of space, making it ideal for use on carpets, rugs, and mats of various sizes.

Say goodbye to the danger of slippery rugs with Fiber-Lok Non-skid Rug Backing. It's the perfect solution for anyone who wants to enjoy their carpets without the worry of slipping or falling.

- Easy to apply

- Leaves no stains

- Machine washable

- Covers up to 30 square feet

10. Elmer's Products E7000 Carpenters Wood Glue, 4 Fl Oz, Yellow, 4 Fl Oz

The Carpenter's Wood Glue is a must-have for carpentry and home repairs. This 4-ounce bottle is perfect for small and medium-sized woodworking projects. It is easy to use and clean up with soap and water when the glue is still wet. Once it dries, you can scrape and sand it to your desired finish. This wood glue has a 20 to 30 minute clamp time and takes 24 hours to achieve a full bond.

One of the best features of this product is that it is non-toxic, making it safe for use around the house. It does not emit any harmful fumes, making it ideal for indoor use. You can rely on this glue to bond stronger than wood, making it a great choice for furniture and other woodworking projects.

- Non-toxic and safe for use around the house

- Easy to clean up with soap and water

- Bonds stronger than wood

- Ideal for small and medium-sized woodworking projects

Best Glue For Engineered Hardwood On Concrete FAQs

Are there any specific preparation steps required before using glue for engineered hardwood on concrete?

Yes, there are specific preparation steps that need to be taken before using glue for engineered hardwood on concrete. First, the concrete surface needs to be thoroughly cleaned and dried. Any dust, debris, or grease needs to be removed. A concrete sealer can be applied to improve adhesion. Next, a moisture barrier needs to be applied to prevent moisture from seeping through the concrete and damaging the hardwood. This can be achieved by applying a layer of epoxy or polyurethane moisture barrier directly onto the concrete surface. The adhesive manufacturer's instructions should be followed carefully in terms of application and curing time. It's important to note that the moisture content of the concrete needs to be tested prior to installation to ensure that it falls within the recommended range. If the moisture content is too high, it can lead to warping, buckling or other damage to the hardwood. Overall, proper preparation is key to ensure a successful installation of engineered hardwood on concrete.

Can a moisture barrier be used with the glue for engineered hardwood on concrete?

Yes, a moisture barrier can be used with the glue for engineered hardwood on concrete. In fact, it is highly recommended to use a moisture barrier to prevent any moisture from seeping through the concrete and causing damage to the hardwood flooring. Moisture barriers act as a protective layer between the concrete and the hardwood flooring, preventing any moisture from penetrating through.

When installing engineered hardwood on concrete, it is important to ensure that the concrete is dry and free from any moisture before installing the moisture barrier. The moisture barrier should be installed in a continuous layer over the entire surface of the concrete, with overlapping seams to ensure complete coverage.

After the moisture barrier is installed, the glue can be applied to the concrete and the engineered hardwood can be installed on top. It is important to follow the manufacturer's instructions for the glue and engineered hardwood installation to ensure a successful installation.

Overall, using a moisture barrier with the glue for engineered hardwood on concrete is a wise choice to protect your investment and ensure the longevity of your hardwood flooring.

Can the glue for engineered hardwood on concrete be used for other types of flooring installations?

The glue used for engineered hardwood on concrete cannot be used for all types of flooring installations. It is specifically designed for this type of installation, as it needs to be strong enough to hold the hardwood planks in place on a concrete subfloor. Other types of flooring, such as laminate or vinyl, may require a different type of adhesive that is better suited for their specific installation requirements.

Furthermore, different flooring types have different installation methods, and the adhesive used may vary depending on the installation method. For example, some flooring may be installed using a click-lock system, which does not require any adhesive at all. In contrast, other types of flooring may require a full spread adhesive application.

Therefore, it is important to consult with a flooring professional or follow the manufacturer's recommended installation guidelines to ensure that the appropriate adhesive is used for your specific flooring type and installation method. Using the wrong adhesive can result in a failed installation and costly repairs.

How long does the glue take to dry when laying engineered hardwood on concrete?

The time it takes for glue to dry when laying engineered hardwood on concrete can vary depending on the specific type of adhesive being used. Generally, it can take anywhere from 24 to 48 hours for the glue to fully dry and cure. However, it is important to note that factors such as temperature, humidity, and ventilation can also impact the drying time.

It is recommended to follow the manufacturer's instructions for the specific adhesive being used and to ensure that the concrete surface is clean, dry, and free of any debris before laying the hardwood. Additionally, it may be helpful to acclimate the hardwood to the room's temperature and humidity before installation to prevent any warping or damage.

Overall, while the drying time for glue when laying engineered hardwood on concrete may take a couple of days, it is important to properly prepare and follow the instructions for a successful and long-lasting installation.

What type of glue is best for laying engineered hardwood on concrete?

When it comes to laying engineered hardwood on concrete, the type of glue you choose is crucial to the success of your project. The best type of glue for this purpose is a high-quality polyurethane-based adhesive. This type of adhesive is specifically designed for bonding wood to concrete and offers excellent bond strength, durability, and moisture resistance.

Additionally, polyurethane-based adhesive is easy to use and requires minimal preparation. Before applying the adhesive, make sure the surface of the concrete is clean and free of any debris or contaminants. Apply the adhesive to the concrete using a trowel or notched trowel, then lay the engineered hardwood onto the adhesive.

It's important to note that not all adhesives are suitable for use with engineered hardwood on concrete, and using the wrong type of adhesive can result in a failed installation. Therefore, it's always best to consult with a flooring professional or manufacturer to ensure you choose the right adhesive for your specific project.