If you’re looking for a way to enhance the strength and durability of your carbon fiber materials, epoxy is the way to go. Epoxy for carbon fiber is a popular material that is used by many individuals for a variety of purposes such as automotive parts, aerospace, and sports equipment. However, before making a purchase, it’s crucial to consider some key factors to ensure that you are getting the right type of epoxy for your specific needs.

One of the essential factors you need to think about is the type of fiber that you are using. Different fibers require different types of epoxy, so it’s important to do your research and determine which type of epoxy is right for you. Another aspect that you need to consider is the type of curing process that you prefer. Epoxy can cure under many different conditions, from simple room temperature to more complex thermal curing methods.

Are you looking for an epoxy that is suitable for high-temperature use? Are you considering an epoxy that provides exceptional strength and resistance to impact? Do you want an epoxy that provides a smooth and clear finish when applied? These are just some of the questions you might have when searching for the right epoxy for carbon fiber. Keep in mind that there are many options available, so look around and compare products to find the one that best suits your needs. With the right epoxy, you can help ensure that your carbon fiber materials are as durable and long-lasting as possible.

10 Best Epoxy For Carbon Fiber

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

This product is ideal for repairing and strengthening objects using carbon fiber fabric and epoxy resin.

|

|

||

|

2

|

Ideal for repairing flat concrete cracks using an epoxy and carbon fiber kit, suitable for DIY projects.

|

|

||

|

3

|

The product is ideal for repairing walls with heavy-duty carbon fiber fabric and epoxy, which can support up to 480 grams.

|

|

||

|

4

|

Ideal for sealing and stabilizing composites made of carbon, fiberglass, epoxies, and resins using ultra-elite lab vacuum supplies.

|

|

||

|

5

|

The product is ideal for repairing cracks in concrete structures such as basements and foundation walls, providing high strength reinforcement.

|

|

||

|

6

|

This product is ideal for wrapping automotive surfaces with a high gloss carbon fiber finish.

|

|

||

|

7

|

Ideal for repairing and reinforcing structural components with high strength and lightweight properties using carbon fiber fabric and epoxy resin.

|

|

||

|

8

|

The product is ideal for building and repairing lightweight, high strength structures in the automotive, aerospace, and boating industries.

|

|

||

|

9

|

Ideal for adding a high gloss carbon fiber look to automotive exteriors or interiors.

|

|

||

|

10

|

This carbon fiber cloth mat is suitable for use in auto, aerospace, and boat builds and repairs with epoxy and resin compatibility.

|

|

1. Carbon Fiber Repair Kit: 36×14 Sheet+16oz Epoxy

Looking for a versatile and strong Carbon Fiber Kit? Look no further! This kit is perfect for a variety of applications, including hoods, custom gauges, marine projects, and more! Even home projects can benefit from this economical and easy-to-use kit. The Carbon Fiber Kit is UV stable and chip resistant, ensuring that your projects look great for years to come.

The kit includes everything you need to get started: an 8 oz bottle of Epoxy, a 4 oz bottle of Hardener, and a 36" x 14" Carbon Fiber Cloth. Each component is securely packaged in a strong cardboard roll, ensuring that it arrives at your doorstep in pristine condition.

Mixing the epoxy and hardener is a breeze. Simply mix 2 parts A (Epoxy) to 1 part B (Hardener) in a clean, new container for 2 minutes. Be sure to scoop the sides and bottom while mixing to ensure a thorough mix. Once the mixture is ready, apply it onto the carbon fiber cloth using a paint brush or roller.

Once dry, the carbon fiber will not be flexible and will have a beautiful shine to it. If you're not fully satisfied with the product, you can get a full refund. Contact the manufacturer anytime after purchase and they will make it right. With this Carbon Fiber Kit, you can tackle any project with confidence!

- Versatile and strong, perfect for a variety of applications

- UV stable and chip resistant for long-lasting projects

- Economical and easy-to-use

- Includes everything you need to get started

- Produces a beautiful shine once dry

- Comes with a 110% satisfaction guarantee

2. Stitchdog Diy Concrete Crack Repair Kit 4000 For Flat Crack Repair, Epoxy And Carbon Fiber

The Fast & Simple Concrete Crack Repair is an efficient solution for repairing cracks in concrete surfaces. This product is designed to provide a permanent and structural repair to cracks in concrete. It is easy to use and does not require any special skills or tools.

With this product, you can repair cracks in concrete slabs, floors, walls, and other surfaces quickly and easily. The Fast & Simple Concrete Crack Repair is a two-part system that includes a liquid polymer and a cementitious powder. The liquid polymer is mixed with the cementitious powder to create a paste that is applied to the crack. The paste hardens quickly, providing a permanent and strong repair.

The Fast & Simple Concrete Crack Repair is ideal for both interior and exterior use. It is resistant to water, chemicals, and UV rays, making it suitable for use in harsh environments. This product can also be used to repair cracks in concrete structures such as bridges, highways, and parking garages.

Overall, the Fast & Simple Concrete Crack Repair is an excellent choice for anyone looking for an easy and effective way to repair cracks in concrete. It is a permanent and structural solution that provides long-lasting results.

- Fast and easy to use

- Provides a permanent and structural repair

- Suitable for both interior and exterior use

- Resistant to water, chemicals, and UV rays

- Can be used to repair cracks in concrete structures

- – May not be suitable for very large cracks

- – Requires careful mixing of the liquid polymer and cementitious powder

- – May be slightly more expensive than other crack repair products

3. Carbon Wall Repair Kit: Easy Install – High Strength!

The High Strength 6-inch wide Twill Carbon Fiber Patch with a weight of 480 grams/meter is an ideal product for repairing damaged walls. The patch has superior bonding and can be easily secured with the help of a self-mixing 2-part FastFix high strength epoxy that comes with the kit. The installation process is simple and requires only 5 easy-to-follow steps, which ensure long-lasting results. The fabric sets dry in just 24 hours and when bonded to the wall, it becomes nearly impossible to remove. The kit includes everything you need to complete the repair, making it an easy and convenient solution to fix damaged walls.

- High strength 6-inch wide Twill Carbon Fiber Patch

- Superior bonding

- Self-mixing 2-part FastFix high strength epoxy

- Easy to install with 5 simple steps

- Sets dry in 24 hours

- Nearly impossible to remove when bonded to wall

- Comes with everything needed to complete repair

4. Elite Carbon Fiber Vacuum Bagging Kit.

Achieve better composite parts with the Fibre Glast Vac Bag Starter Kit, designed to make your manual layups even better. This kit features high-quality fittings, clamps, tubes, couplings, and a vacuum pressure gauge and regulator that are all compatible and reusable. The degassing process removes excess resin, air, and humidity after wet layup, resulting in stronger and lighter fiberglass, carbon, and Kevlar parts for elite performance and appearance.

This kit comes with free professional instruction, including detailed instructions and guided videos to assist you in improving your DIY builds, repairs, castings, and laminates. Fibre Glast only sells fabrics that are certified for the most demanding applications, ensuring that there are no flaws or variations in product quality from one order or batch to the next. Fibre Glast prides itself on being the trusted supplier of governments, contractors, and major brands such as the US Olympic Luge Team, and they are committed to earning your trust as well.

- High-quality fittings, clamps, tubes, couplings, vacuum pressure gauge, and regulator included in kit

- Degassing process removes excess resin, air, and humidity for stronger and lighter composite parts

- Free professional instruction provided, including detailed instructions and guided videos

5. Crack-Fix Complete: Carbon Fiber Concrete Repair Kit

The Easy-to-install High-Strength Patch Reinforcement kit is a perfect solution for repairing cracks and holes in concrete or cinderblock walls. This kit includes everything you need to reinforce walls using a 12K-480grm KARBXON Carbon Fiber patch and Fastfix-it epoxy adhesive. Even beginners can install this kit with ease and without any hassle.

Thanks to the use of KARBXON Carbon Fiber, this patch reinforcement is highly durable and can withstand heavy loads. The Fastfix-it epoxy adhesive provides high bonding strength and ensures a long-lasting repair solution. This kit can be used for both residential and commercial applications, making it a versatile and cost-effective solution.

With this kit, you can reinforce walls in a matter of hours and restore their structural integrity. This kit is perfect for DIY enthusiasts who want to save money on expensive repairs without compromising on quality.

Overall, the High-Strength Patch Reinforcement kit is a reliable and easy-to-use solution for reinforcing walls. With its high-strength carbon fiber patch and fast-acting epoxy adhesive, this kit provides a long-lasting, cost-effective repair solution.

- Easy to install, even for beginners

- High-strength 12K-480grm KARBXON Carbon Fiber patch reinforcement

- Fastfix-it epoxy adhesive provides strong bonding

- Includes everything you need for the installation

- Suitable for both residential and commercial applications

- – May not be suitable for larger-scale repairs

6. Vvivid Epoxy High Gloss Carbon Fiber Automotive Vinyl Wrap (25ft X 5ft, Black)

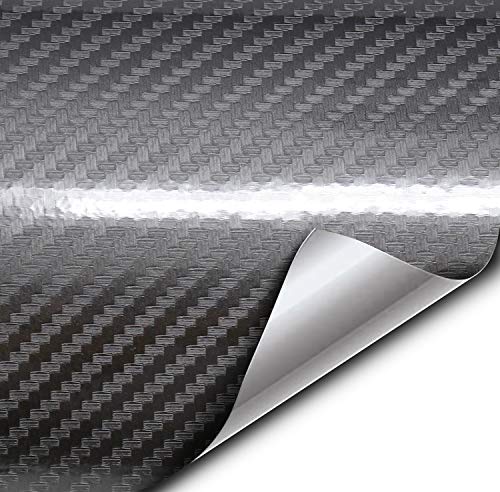

Introducing the XPO series Tech Art vinyl – the perfect solution for achieving a hyper-realistic carbon fiber look on your vehicle's interior parts, trims, dash, cabinets, tables and more! With a super high gloss finish and scratch protection coating, this vinyl is designed to last for 10 years or more, making it a reliable and long-lasting option for all your interior design needs. Measuring at 6.5 mils thick, the XPO series Tech Art vinyl is easy to apply and provides a durable, high-quality finish that is sure to impress.

Whether you're looking to upgrade your car's interior or add a touch of style to your home decor, the XPO series Tech Art vinyl is the perfect choice. So why wait? Order yours today and experience the ultimate in hyper-realistic carbon fiber design!

- Super high gloss finish for a professional and stylish look

- Scratch protection coating for added durability and long-lasting use

- Easy to apply and measures at 6.5 mils thick

7. Carbonpro Cloth: High-Strength Aerodynamic Fabric

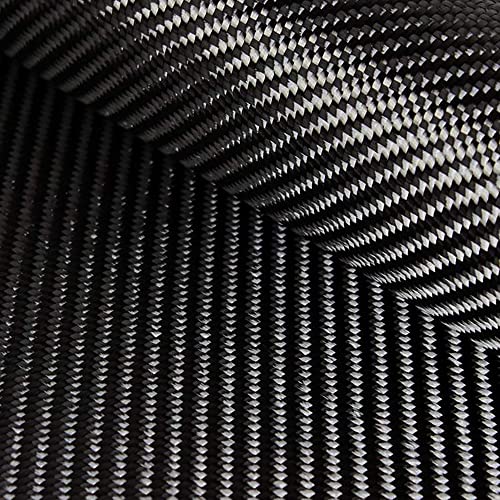

The Carbon Graphite Fiber by Fibre Glast is a sleek black 3K twill-weave fabric that delivers the ultimate tensile strength, lightweight performance, and professional cosmetics. This fabric is great for watercraft, aircraft, or auto-making and should be used with epoxy-resin. It is 6 oz, 50 in x 108 in in size.

The Aerodynamic Fabric is made from woven carbon that improves performance and maximizes strength. This top-quality graphite fabric is perfect for custom reinforcements, car parts, boat builds, plane or drone models, prosthetics, sporting goods, equipment, or structural forms.

This fabric is First Quality Certified, which means that it has been certified for the most demanding applications, from marine craft to space craft. There will be no flaw or difference in the product from one order or batch to the next.

To use this carbon twill weave, follow the guided instructions or use your own expertise to apply it to your repair, build, tool, or part. The stealth black graphite mat is a great alternative to fiberglass roving, mesh cloth, or tape in many fabrications.

At Fibre Glast, we take pride in being the trusted supplier of governments, contractors, and big brands like the US Olympic Luge Team. We look forward to earning your trust as well.

- Ultimate tensile strength

- Lightweight performance

- Pro cosmetics

- Top-quality graphite

- First Quality Certified

- Great alternative to fiberglass roving, mesh cloth, or tape

8. Vvivid 5d High Gloss Grey Epoxy Carbon Fiber Automotive Vinyl Wrap Film Roll (20 Foot By 5 Foot)

Introducing the VViViD Epoxy 5D Gloss Carbon, the superior carbon fiber vinyl film that offers a super realistic carbon weave. This vinyl film boasts an extremely high gloss finish, thanks to VViViD's unique 'thermoformable' floating lamination. With a thickness of 6.5 mils, this vinyl film is highly durable and scratch-resistant, making it stand out from other carbon fiber vinyls in the market. It is perfect for interior use, such as trims, dash, cabinets, tables, and more! With a lifespan of up to 10+ years, you can be sure that your investment will last for a long time.

The VViViD Epoxy 5D Gloss Carbon is perfect for people who want to add a touch of style to their interior design. This vinyl film is easy to apply and will give your car or furniture a unique, high-gloss finish that will make it stand out from the crowd. The realistic carbon weave is so authentic that it will be hard to differentiate it from the real thing.

This vinyl film is not only stylish but also highly durable. It is scratch-resistant and can last up to 10+ years, making it a great investment for people who want to improve the look of their car or furniture. With a thickness of 6.5 mils, this vinyl film is tough enough to withstand daily wear and tear, making it ideal for high-traffic areas.

Overall, the VViViD Epoxy 5D Gloss Carbon is an excellent choice for people who want to add a touch of elegance and style to their interior design. Its high gloss finish, realistic carbon weave, and durability make it stand out from other carbon fiber vinyls in the market.

- Super realistic carbon weave

- Extremely high gloss finish

- Highly durable and scratch-resistant

- Easy to apply

- Lifespan of up to 10+ years

- – Only for interior use

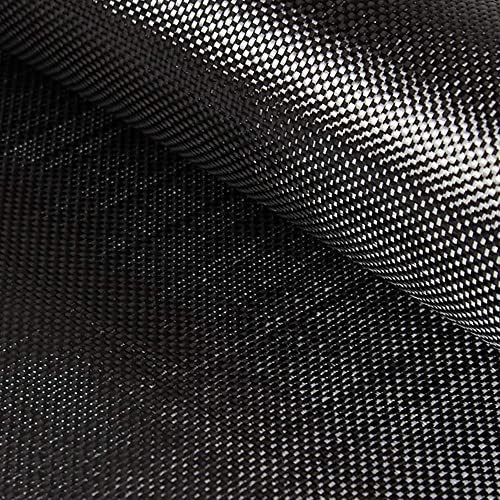

9. Carbon Cloth Mat – High Strength Lightweight Graphite

The Carbon Graphite Cloth Mat by Fibre Glast is a sleek and professional-looking black plain-weave fabric that offers ultimate tensile strength and lightweight performance. Measuring 50 inches by 180 inches, this 6 oz fabric is ideal for use in watercraft, aircraft, or auto-making. It works best with epoxy-resin for better bonding. The woven 3K carbon fiber makes it perfect for improving performance and maximizing strength on custom reinforcements, car parts, boat builds, plane or drone models, prosthetics, sporting goods, equipment, or structural components.

Fibre Glast sells only first-quality certified fabrics that are suitable for the most demanding applications, from marine craft to space craft. "First Quality" means that there will be no flaws or differences in product from one order or batch to the next. This ensures that you get the best quality product every time.

Using this carbon plain weave is easy. Follow the guided instructions or use your own expertise to apply it to your repair, build, tool, or part. The stealth black graphite mat is a great alternative to fiberglass roving, mesh cloth, or tape in many fabrications. It delivers professional-looking cosmetics and great performance.

Fibre Glast is a trusted supplier of governments, contractors, and big brands like the US Olympic Luge Team. They are committed to providing top-quality products and earning their customers' trust.

- Sleek and professional-looking black plain-weave fabric.

- Offers ultimate tensile strength and lightweight performance.

- Woven 3K carbon fiber makes it perfect for improving performance and maximizing strength.

- Ideal for use in watercraft, aircraft, or auto-making.

- First-quality certified fabrics suitable for the most demanding applications.

- Great alternative to fiberglass roving, mesh cloth, or tape in many fabrications.

- Easy to use.

Best Epoxy For Carbon Fiber FAQs

Can any epoxy be used with carbon fiber or are there specific types?

When it comes to using epoxy with carbon fiber, there are certain types of epoxy that are better suited for the job than others. Carbon fiber is an extremely strong and lightweight material, which means that it requires an epoxy that can bond with it properly and provide the necessary strength and durability.

One of the most important factors to consider when choosing an epoxy for carbon fiber is its cure time. The epoxy needs to cure quickly enough to prevent any potential damage to the carbon fiber during the bonding process. Additionally, the epoxy needs to be compatible with the type of carbon fiber being used, as well as any other materials that may be involved in the project.

There are many different types of epoxy available on the market, and not all of them are suitable for use with carbon fiber. It is important to choose an epoxy that is specifically designed for use with composite materials like carbon fiber, and to follow the manufacturer's instructions carefully to ensure a successful bond. Overall, using the right epoxy is crucial for achieving a strong and durable bond with carbon fiber.

How does the ratio of epoxy to carbon fiber affect the strength of the composite material?

The ratio of epoxy to carbon fiber is a critical factor that influences the strength of composite materials. The strength of composite material depends on the amount of carbon fiber present in the matrix of epoxy. Carbon fiber is a lightweight, high-strength material that has excellent mechanical properties. Epoxy, on the other hand, is a thermosetting polymer that acts as a binder to hold the fibers together.

The optimal ratio of epoxy to carbon fiber depends on the specific application and the desired mechanical properties of the composite material. In general, increasing the amount of carbon fiber in the composite material improves its strength and stiffness. However, if the amount of carbon fiber is too high, the overall toughness and impact resistance of the composite material may decrease.

Moreover, the quality of the bond between the carbon fibers and the epoxy matrix is also crucial to the strength of the composite material. Proper curing of the epoxy is essential to ensure a strong bond between the fibers and the matrix. In summary, the ratio of epoxy to carbon fiber is a crucial factor in determining the mechanical properties of composite materials, and it should be carefully considered during the design and manufacturing process.

What are the advantages of using epoxy for carbon fiber?

Epoxy is considered one of the most popular resins used in the construction of carbon fiber composites due to its various advantages. Firstly, epoxy is known for its excellent adhesive qualities which results in a strong and long-lasting bond between the carbon fiber and the epoxy resin. This ensures that the carbon fiber composite is durable, strong, and able to withstand various environmental conditions.

Secondly, epoxy resins are known for their high strength-to-weight ratio, which means that the composite material is lighter and stronger than other materials. This makes epoxy an ideal material for use in applications such as aerospace, automotive, and marine industries where weight reduction is critical for performance.

Lastly, epoxy resins have a high level of chemical resistance which makes the composite material resistant to corrosion, chemicals, and other types of damage. This makes it an ideal material for use in harsh environments such as chemical plants, oil rigs, and other industrial applications.

In conclusion, the advantages of using epoxy for carbon fiber include its excellent adhesive qualities, high strength-to-weight ratio, and high chemical resistance, making it an ideal material for use in various industries.

What are the common techniques for applying epoxy to carbon fiber?

There are several common techniques for applying epoxy to carbon fiber. The first step is to clean the surface of the carbon fiber thoroughly to remove any dirt or debris. Next, the epoxy is mixed according to the manufacturer's instructions and applied to the carbon fiber using a brush, roller, or spray gun. It is important to apply the epoxy evenly and avoid creating air bubbles. Once the epoxy is applied, it needs to be left to cure for the recommended amount of time, usually between 24-48 hours. After the epoxy has cured, the surface can be sanded and polished to achieve a smooth finish. Another common technique is to vacuum-bag the carbon fiber and epoxy to ensure even pressure and reduce the risk of air bubbles. This method is commonly used in aerospace and high-performance sports equipment manufacturing. Overall, the key to successfully applying epoxy to carbon fiber is to follow the manufacturer's instructions carefully and take the time to ensure a smooth, even application.

What is the curing time for epoxy and carbon fiber composites?

The curing time for epoxy and carbon fiber composites can vary depending on several factors such as the type of epoxy used, the ambient temperature and humidity, and the complexity of the composite structure. Typically, the curing time for epoxy and carbon fiber composites can range from a few hours to several days.

During the curing process, the epoxy resin undergoes a chemical reaction, transforming from a liquid state to a solid state. The curing process is critical to the final strength and durability of the composite structure.

To ensure proper curing, it is essential to follow the manufacturer's instructions for mixing and applying the epoxy resin. It is also important to control the ambient temperature and humidity during the curing process. Sometimes, heat or pressure is applied to expedite the curing process.

In summary, the curing time for epoxy and carbon fiber composites can vary, but it is a critical step in producing high-quality, durable composite structures.