If you're looking for a unique and traditional way to fire your pottery pieces, then clay for pit firing may just be what you're looking for. This method of firing dates back to ancient times and allows for beautiful and unpredictable finishes on your pottery creations.

Before diving into buying clay for pit firing, there are a few factors to consider. Firstly, the type of clay you use will greatly affect the finished product. Some clays may be more porous and therefore absorb smoke and ash more deeply, creating intricate patterns and textures. Additionally, be sure to consider the size of your pieces and the depth of your pit, as these factors will impact the firing process.

If you're a pottery enthusiast or someone who enjoys exploring traditional techniques, then you may have some questions about clay for pit firing. What are the benefits of using this method of firing? How can you ensure consistent and successful results? Are there any safety precautions to take when working with pit firing? These questions and more can be answered through careful research and experimentation.

In conclusion, clay for pit firing offers a unique and traditional way to create beautiful finishes on your pottery pieces. By considering the type of clay used and other factors, you can ensure consistent results and a successful firing process. Be sure to do your research and experiment to fully understand the benefits and techniques of pit firing.

10 Best Clay For Pit Firing

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

This product is ideal for insulating kilns, ovens, forges, fireplaces, and fire pits during metal clay firing and jewelry soldering.

|

|

||

|

2

|

The product is ideal for providing fireproof insulation for kilns, ovens, forges, metal clay firing, fireplaces, and jewelry soldering.

|

|

||

|

3

|

Ideal for sculpting clay projects at home or in the classroom without the need for a kiln or firing process.

|

|

||

|

4

|

Ideal for creating pottery and sculptures with a classic terracotta look, suitable for low fire kilns.

|

|

||

|

5

|

This product is ideal for tea lovers in search of a large capacity, handmade, vintage teapot made from purple clay.

|

|

||

|

6

|

This product is ideal for replacing firebricks in US Stove FBP6 models, with a size of 9" x 4-1/2" x 1-1/4".

|

|

||

|

7

|

This product is ideal for building high temperature structures like kilns, forges, and furnaces used in metalworking and jewelry making.

|

|

||

|

8

|

This product is ideal for melting and firing jewelry, metals, clay, enamel, and beads in a tabletop kiln.

|

|

||

|

9

|

This product is ideal for sculpting and throwing pottery on a pottery wheel, as well as firing the finished product.

|

|

||

|

10

|

This product is ideal for sculpting, throwing on a pottery wheel, firing and other pottery-related activities.

|

|

1. Insulbrick: Ultimate Fire Accessory For Metal Art.

The HTINXED Insulating Fire Bricks are a cost-effective solution for those in need of high-quality insulating bricks. Made of refractory clay, alumina, and silica mixed materials, these bricks have a porous structure and can withstand temperatures of up to 2462°F/1350°C. With their strong insulation performance and low heat storage, they can achieve rapid heating, shorten the heating time, save energy and cost. These bricks are easy to install and can be easily moved and cut thanks to their low density and light weight. Each brick measures 9" x 4.5" x 2.5" and weighs 1.7KG. They can be cut into various sizes to match your equipment accurately, allowing you to obtain a closer fire resistance effect. These insulating bricks can be used widely for various household and industrial purposes, such as oven, pizza oven, wooden fire oven, wall stove insulation, outdoor oven, outdoor kitchen, outdoor barbeque, kiln repair, jewelry welding, clay pottery firing, various electric furnace linings, and glass melting, metal smelting, refining vessels, and heaters. The packaging box for the Insulating Fire Bricks is customized and tightly packed to prevent the bricks from colliding with each other and breaking in the box during transportation. Additionally, each box has a fragile label to remind the courier to handle it with care. In case the insulating fire bricks are cracked or severely worn due to improper transportation, the seller will provide new insulating fire bricks free of charge.

- High-performance insulating bricks at a lower price

- Strong insulation performance and high temperature resistance

- Can achieve rapid heating, shorten the heating time, save energy and cost

- Easy to move and cut

- Can be used for various household and industrial purposes

- Customized and tightly packed packaging box to prevent damage during transportation

- Free replacement of insulating fire bricks in case of damage during transportation

- – Edges of the bricks may be slightly worn and slag off due to the material's softness

2. Heatshield: Ultimate Fire Safety Blanket

Porcelain fiber products are ceramic fiber-based industrial products that are lightweight, with a thickness of 20mm, and can withstand strong mechanical vibrations. They are ideal for use in high-pressure and abrasive environments. These products are asbestos-free, have low thermal conductivity and shrinkage, and are non-toxic. They have been tested to handle temperatures up to 2400F (1315C).

These ceramic fiber products are easy to cut and shape with a sharp knife or heavy scissors. They are soft and flexible enough to mold into the required shape for installation. They are commonly used in wooden stoves, baffles, fireplaces, furnaces, pellet stoves, chimneys, boilers, pizza ovens, brazing, soldering, welding, foundry, pottery kilns, refractory, glass blowing, and more.

Furthermore, ceramic blankets are widely used in the steel industry, petrochemical industry, power generation, glass furnace crown insulation, insulation of commercial dryers and ovens, and for fire protection purposes.

- Can withstand high pressure and abrasive environments

- Asbestos-free and non-toxic

- Tested to handle temperatures up to 2400F (1315C)

- Easy to cut and shape with a sharp knife or heavy scissors

- Soft and flexible enough to mold into the required shape for installation

- Suitable for a wide range of applications including wooden stoves, furnaces, and pottery kilns

- Widely used in steel industry, petrochemical industry, and power generation

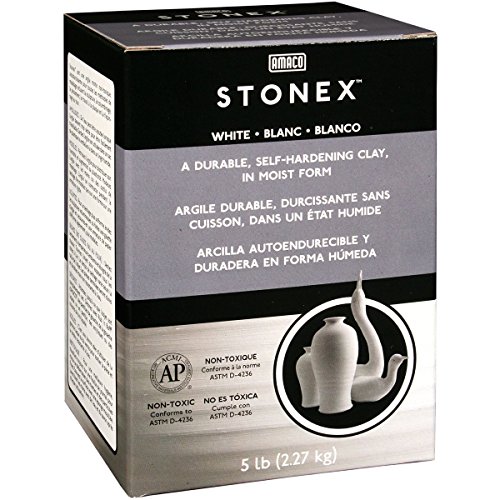

3. Amaco Stonex™ Self-Hardening Clay, 5 Lbs.

This self-hardening clay comes in a moist form and is ready to use. It is easy to work with and can be hardened by adding water if it begins to dry out. Once dry, the clay can be decorated with a variety of paints, including Rub n Buff, school paints, temperas, acrylics or liquid crayons. This clay is proudly made in the USA.

- Ready-to-use moist form

- Easy to work with

- Can be decorated with various paints

- Made in the USA

4. Amaco Low Fire Terra Cotta 77 Earthenware Clay – Moist – 50 Lbs.

This low-fire earthenware clay is perfect for crafters and expressionists of all ages. It comes in a 50-pound package and is easy to blend, which helps resist cracking, shrinkage, and warping. The clay can be fired at temperatures ranging between 06-5, which results in a beautiful terra cotta color to darker red-brown finish. Whether you're creating sculptures or pottery, this clay is sure to meet all your needs and provide a great experience.

The 50-pound package is perfect for making large sculptures or pottery.

Low-fire earthenware clay is easy to blend and resists cracking, shrinkage, and warping.

Fires at 06-5, resulting in beautiful terra cotta to darker red-brown finish.

- Ideal for crafters and expressionists of all ages

- Resists cracking, shrinkage, and warping

- Fires at 06-5 to beautiful terra cotta to darker red-brown finish

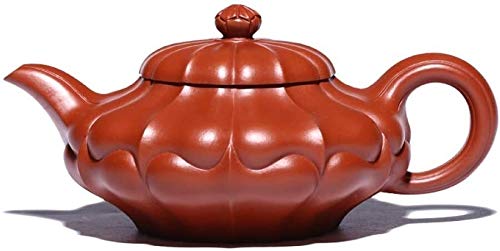

5. Hizljj Handmade Vintage Yixing Teapot Set

Experience the true essence of tea with this handmade tea set made from China Yixing raw ore purple clay. The use of environmentally friendly and healthy materials ensures that there are no harmful chemicals that can affect the quality of your tea. The professional master craftsman ensures that each set is made with utmost care and precision, giving you a product that is both beautiful and functional. The set comes packed in a beautiful gift box, making it an ideal Christmas gift for your dad, husband, brother or anyone who loves tea.

The tea set has a capacity of 350ml, perfect for brewing and enjoying your favorite tea. The traditional production method ensures that the set retains the natural flavor of the tea and enhances the realm of spiritual life. With this tea set, you can make a cup of good tea and taste it whenever you are free. The set will not only enhance your tea-drinking experience but also add a touch of elegance to your home.

Our tea set is designed to bring convenience to your life and let you experience the joy of life during use. The set is easy to clean and maintain, ensuring that you can enjoy your tea without any hassle. Experience the beauty and elegance of this handmade tea set and enjoy a cup of good tea that will make your life more tasteful.

- Made from China Yixing raw ore purple clay, ensuring the use of environmentally friendly and healthy materials

- Handmade by professional master, ensuring each set is made with utmost care and precision

- Packed in a beautiful gift box, making it an ideal Christmas gift

- Capacity of 350ml, perfect for brewing and enjoying your favorite tea

- Traditional production method ensures that the set retains the natural flavor of the tea and enhances the realm of spiritual life

- Easy to clean and maintain, ensuring hassle-free tea-drinking experience

6. Renew Your Stove With Protalwell Fire Bricks

Upgrade your fireplace or stove with these Vermiculite Material Fire Bricks. These bricks are specially designed to withstand high temperatures of up to 2200F, providing a strong thermal insulation performance. They not only help you save wood but also save money in the long run. These firebricks are not as brittle as clay bricks and do not peel off easily after burning. They are the perfect replacement for your old firebricks.

Measuring 9″ x 4.5″ x 1.25″, these firebricks are a common size for most stoves and fireplaces. They are the same size as the service part 1-00-900450125 for Harman and FBP6E for US Stove. The precise size of these bricks makes them easy to install and ensures that there are no gaps left. The flat surface of the firebricks ensures that the combustion chamber is sufficiently flat after installation, making it beautiful and easier to clean.

These Vermiculite Material Fire Bricks offer you an affordable and durable solution for your fireplace or stove. They are easy to install, provide excellent insulation, and are built to last. Upgrade your heating system today with these high-quality firebricks.

- Can withstand high temperatures of up to 2200F

- Offers strong thermal insulation performance

- Helps save wood and money

- Not as brittle as clay bricks

- Same size as most stoves and fireplaces replacement parts

- Easy to install and won't leave gaps

- Flat surface ensures sufficient combustion chamber after installation

- Beautiful and easy to clean

7. Heatmaster Fire Bricks – Ultimate Kiln Insulation!

The Insulating Fire Brick is a high-quality product made of alumina and silica. It is a soft refractory brick that saves energy by consuming only half the energy of hard refractory bricks during the heat transfer process. With a uniform porous structure, these fire bricks for forge have excellent insulation properties and can withstand high temperatures up to 2500°F, thus speeding up the heating process.

The Insulating Fire Bricks have lower heat storage compared to concentrated bricks, resulting in decreased fuel costs and faster heat-ups in alternately operated heating equipment. Moreover, these bricks are easy to store and move around the construction site due to their light weight. They are not easily damaged due to climatic changes and can be stored in a dry place.

These Insulating Fire Bricks have a wide range of applications for both home and industrial use. They can be used in ovens, stoves, glass making, clay pottery, Fire Bricks kilns, iron and steel industries, nonferrous metal industries, refining vessels, heaters and more. The product comes with a guarantee. If customers are not satisfied with their purchase or the product is damaged during transit, they can contact the seller for a prompt solution.

- Made of high-quality alumina and silica

- Soft refractory brick that saves energy

- Excellent insulation properties and can withstand high temperatures

- Lower heat storage results in decreased fuel costs and faster heat-ups

- Easy to store and move around the construction site

- Wide range of applications for both home and industrial use

- Comes with a guarantee

8. Rapidfire Tabletop Kiln: Jewelry & Metal Melter

The RapidFire Pro-L Kiln is a must-have for professional artists who value portability, function, and performance. This product offers excellent value for money and is a cost-effective alternative to other comparable products on the market. With a heating capability of up to 2200°F (1200°C) in just 8 to 10 minutes, it is perfect for artists who need a quick and efficient solution to their firing needs.

The kiln's large firing chamber (6" x 6" x 5") offers ample space for multiple projects, while its front-loading door ensures easy access. It is designed with a digital temperature controller (1500 watts of power) that can handle several projects at once. Weighing just 12 lbs, it is ultra-portable and comes with a convenient carrying handle that makes it easy to transport.

Whether you're a professional artist looking for an efficient and reliable kiln, or a beginner who wants to take their work to the next level, the RapidFire Pro-L Kiln is the perfect solution. With its combination of portability, function, and performance, it is sure to meet all your firing needs.

- Heats up to 2200°F (1200°C) in just 8 to 10 minutes

- Large firing chamber (6" x 6" x 5") with a front-loading door for easy access

- Digital temperature controller (1500 watts of power) can handle multiple projects

- Weighs only 12 lbs and comes with a convenient carrying handle for portability

9. Earthware Sculpting Clay – Low Fire Pottery

The Natural Red Terra Cotta Clay is an excellent choice for those who are into pottery making. This clay is made in the USA, and after firing in the kiln, it will have a beautiful, rich terracotta color. To achieve the best results, the clay should be bisque fired to Cone 04, then glazed to Cone 06. This organic clay is non-toxic, making it safe for use in various crafts. With 5 pounds of clay, you can create multiple small pieces or sculpt and let them air dry. However, please note that if you are air-drying the clay, the finished product will not be permanent and can break if exposed to water or dropped. It is essential to keep in mind that moist clay blocks can be a breeding ground for mold. Although the type of mold that grows on clay is not harmful, it can be smelly. Many potters consider this a desirable trait as it acts as a natural plasticizer.

- Rich terracotta color after firing

- Organic and non-toxic

- Can be used for various crafts

- Mold that grows on clay acts as a natural plasticizer

- – Finished product can break if exposed to water or dropped when air-drying

- – Moist clay blocks can be a breeding ground for mold, which may result in an unpleasant smell

10. Earthware Clay: Low-Fire Throwing & Sculpting Solution.

Create beautiful and long-lasting crafts with the Natural White Clay. This clay is organic, non-toxic, and made in the USA. It can be used for various crafting projects and can be fired in a kiln to produce a nice white piece. For best results, bisque the clay to Cone 04 and then glaze to Cone 06. You can also sculpt and airdry the clay, but note that it will not be permanent and may break if exposed to water or dropped. It is essential to consider that blocks of moist clay are prone to mold growth, which is not harmful but can be smelly. However, many potters appreciate the natural plasticizer that mold provides.

Use the 5-pound bag of Natural White Clay to create multiple small pieces or larger sculptures. The possibilities are endless with this versatile and high-quality clay. Whether you are a beginner or an expert, this clay is perfect for all skill levels. It is an excellent choice for anyone looking for a natural, non-toxic, and durable clay for their next crafting project.

- Organic and non-toxic

- Can be used for various crafting projects

- Produces a nice white piece after firing in kiln

- Can be sculpted and airdried

- High-quality and durable

- – May break if exposed to water or dropped

- – Prone to mold growth

Best Clay For Pit Firing FAQs

Can pit firing be done with low-fire or high-fire clay?

Yes, pit firing can be done with both low-fire and high-fire clay. However, the type of clay used will affect the final result of the pit firing. Low-fire clay has a lower firing temperature and is more porous, which makes it a good choice for pit firing. It can also produce a wider range of colors due to its porosity. High-fire clay, on the other hand, has a higher firing temperature and is less porous, which makes it more durable and less likely to crack or break. However, the colors produced by high-fire clay in pit firing are usually more limited than those produced by low-fire clay. Ultimately, the choice of clay will depend on the desired outcome and the specific techniques used in the pit firing process. It's important to experiment with different types of clay and firing techniques to achieve the desired results.

How does the clay body affect the results of pit firing?

The type of clay body used in pit firing has a significant impact on the final results. Different clay bodies have varying levels of porosity, which affects how the clay absorbs and retains smoke and other elements during the firing process. For instance, clay with high porosity absorbs more smoke and ash, resulting in a darker and more heavily textured surface finish, while low porosity clay produces more subtle effects.

Additionally, the color of the clay body can also influence the outcome of pit firing. Lighter clays tend to produce brighter and more vibrant colors, while darker clays create a more muted palette. The mineral content of the clay can also have an impact on the final results, as some minerals can react with the firing process to produce unique patterns and textures.

Ultimately, the choice of clay body is a crucial decision when it comes to pit firing, as it has a significant impact on the final appearance and texture of the finished piece. Experienced potters and ceramic artists carefully consider the properties of different clay bodies to achieve their desired results.

What are the best firing techniques for achieving desired results with pit firing clay?

Pit firing is an ancient firing technique that has been used by various civilizations throughout history. This firing technique involves placing pottery in a pit, covering it with combustible materials, and setting it on fire. The firing process can take several hours to a few days, depending on the desired result.

To achieve the desired result with pit firing clay, there are a few firing techniques that you can use. Firstly, it's essential to prepare your pottery correctly by ensuring that it's bone dry and free of any moisture. This is because moisture can cause your pottery to crack or explode during firing.

Secondly, you need to create a good fire. For pit firing, wood is the best fuel to use because it produces the right amount of heat and ash. You can use different types of wood to create different effects on your pottery. For example, using hardwood produces a darker color, while using softwood produces a lighter color.

Thirdly, you need to control the temperature and airflow. This can be achieved by placing your pottery in the pit in such a way that it's exposed to the heat and smoke evenly. You can also use different materials to create different effects on your pottery. For example, adding salt to the pit can create a glossy finish on your pottery.

Finally, the length of the firing process will depend on the desired result. If you want a darker color, you'll need to fire your pottery for a more extended period. However, if you want a lighter color, you'll need to fire your pottery for a shorter period.

In conclusion, the best firing techniques for achieving desired results with pit firing clay involve preparing your pottery correctly, creating a good fire, controlling the temperature and airflow, and adjusting the length of the firing process according to the desired result.

What type of clay is best for pit firing?

The best type of clay for pit firing is earthenware clay. This type of clay is able to withstand the high temperatures of pit firing, which can reach up to 1000 degrees Celsius. Earthenware clay is also able to withstand the thermal shock that occurs during pit firing, which can cause other types of clay to crack or break. Additionally, earthenware clay is able to absorb the smoke and ash from the pit firing, which creates unique and beautiful patterns on the pottery. There are different types of earthenware clay available, including red, white, and buff earthenware, each with its own unique properties. It is important to choose a high-quality earthenware clay that is suitable for the desired outcome of the pit firing. Overall, earthenware clay is the best choice for pit firing due to its ability to withstand high temperatures and create beautiful patterns.

What types of surface treatments can be used on clay for pit firing?

Pit firing is a primitive method of firing clay that involves burying the clay in a pit and firing it with wood, sawdust or other combustible materials. The surface treatment of clay is an important aspect of pit firing as it can affect the final appearance and texture of the fired piece. There are various types of surface treatments that can be used on clay for pit firing, including burnishing, terra sigillata, and slip.

Burnishing involves polishing the surface of the clay with a smooth object such as a stone or a spoon. This process compresses the clay particles and creates a smooth, shiny surface that is resistant to water. Terra sigillata is a type of slip made from clay that has been finely ground and sieved. It is applied to the surface of the clay and polished with a smooth object to create a smooth, shiny surface.

Slip is a mixture of clay and water that can be applied to the surface of the clay to create texture and decoration. Different colors can be added to the slip to create patterns and designs on the surface of the clay. Once the surface treatment has been applied, the clay can be pit fired to create a unique and beautiful piece of pottery.