If you're looking for high-quality welding tools for your projects, you might want to consider Chinese-made tools. The Chinese welding tool industry has been growing steadily in recent years, and many Chinese brands have gained a reputation for producing tools that are durable, reliable and affordable.

Before you buy any Chinese tools for welding, there are some factors you should consider. First, you need to make sure the tools meet the safety standards set by your country. You should also pay attention to the quality of the materials and the construction of the tools, as well as the customer service and warranty offered by the manufacturer. Finally, you should think about your specific needs and preferences, such as the types of projects you typically work on and the level of expertise you have in welding.

How can you tell if Chinese-made tools for welding are right for you? Do these tools offer the same level of quality and durability as those made by more established brands? And how can you find the best deals on these tools? Whether you're a professional welder, a DIY enthusiast or a hobbyist, these are all important questions to consider. In this article, we'll explore some of the benefits of Chinese-made welding tools, and provide some tips on how to choose the best ones for your needs.

10 Best Chinese Tools For Welding

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for welding plastic pipes made of PP, HDPE, and LDPE with a handheld extrusion welder gun.

|

|

||

|

2

|

Ideal for welding various metals such as carbon steel, stainless steel, copper, and aluminum alloys with its digital technology.

|

|

||

|

3

|

It is an ideal welding tool for TIG welding, cutting, and stick welding with a wide voltage range.

|

|

||

|

4

|

The product is ideal for socket fusion pipe welding up to 2 inches in size.

|

|

||

|

5

|

This product is ideal for heavy-duty welding and provides protection against fumes and high-altitude environments.

|

|

||

|

6

|

The product is ideal for welding pipes together using a digital socket fusion technique, with a maximum size of 2 inches.

|

|

||

|

7

|

This product is ideal for cutting pipes with precision and ease, making it suitable for industrial or DIY projects.

|

|

||

|

8

|

The product is ideal for welding multiple materials using different processes, with added features like spot timer and auto-set.

|

|

||

|

9

|

The product is ideal for welding and joining materials with a 120V power source.

|

|

||

|

10

|

Ideal for small welding jobs with a portable shoulder strap and inverter power source for easy operation.

|

|

1. Powerpro Extrusion Welding Gun: Effortlessly Weld Plastics

The hot air welding machine is a powerful tool for welding PP/PE hot melt sheets, pipes, and membranes. With a voltage of 220V and a frequency of 50/60Hz, it weighs 6.5kg and has a power wire length of 3m. The hot air blower power is 1600W, welding rod heat power is 800W, and the motor power is 800W. It has an extruding volume of 2kg/h and can weld 3/4mm round welding rods. The machine features a dual heating system that allows the material preheating and welding rod melting to be changeable to avoid welding failure. The temperature display shows the working temperature of the welding rod heating system. The 360-degree rotating hot air/welding nozzle can be adjusted to meet different welding needs. The machine includes Hitachi drill with reliable quality and strong power, and motor cold start protection which prevents operating mistakes.

This hot air welding machine is perfect for welding PP/PE hot melt sheets used in water tanks, plating tanks, water towers, and plastic containers. It's also suitable for welding PP/PE hot melt pipes for pipe flange welding, pipe welding, and repair, as well as PP/PE hot melt membranes like geo membranes and waterproofing membranes.

The set includes a welding shoe, holder, flat welding shoe, corner welding shoe, heating elements for hot air blower, disassembly tools, and an operation manual.

- Dual heating system for reliable welding

- 360-degree rotating nozzle for versatile welding

- Temperature display for easy monitoring

- Motor cold start protection to prevent operating mistakes

- Suitable for welding various types of materials

- – May not be suitable for welding other types of materials

2. Digital Inverter Welder For Multiple Metals

This multi-functional welder machine is capable of welding with both AC and DC current, allowing for the welding of a variety of materials including carbon steel, stainless steel, copper, aluminum, and aluminum alloys. Its user-friendly control panel makes it easy for both professional and non-professional welding workers to operate the machine with ease and proficiency.

Safety is a top priority with this welder machine. It is equipped with an anti-shock device that lowers the voltage of the welding machine when it is in a no-load state, ensuring the safety of production operation. The stick welder also features an automatic shut-off function that is triggered when the grid voltage, output current, and machine temperature exceed set standards.

This welder machine is designed to easily fit your welding needs. Its compact build, multi-functionality, steady welding performance, great welding efficiency, and cost-effective welding cost make it an ideal helper for both industrial and outdoor welding applications. Additionally, this welder machine comes with a foot pedal for remote control, allowing the user to set the maximum welding current using the control panel and control the real welding current by adjusting the pressure on the foot pedal.

- Capable of welding with both AC and DC current

- User-friendly control panel for easy operation

- Equipped with safety features such as an anti-shock device and automatic shut-off function

- Compact build and multi-functionality make it ideal for a variety of welding applications

- Comes with a foot pedal for remote control of welding current

3. Yeswelder Ct2050 Tig Welder/cutter/stick Welder, Wide Voltage Multiprocess Welder

The CT2050 is a versatile welding machine that is capable of AC/DC TIG, AC/DC Pulse TIG, Stick, and Cut operations with built-in and external air compressor, all in one lightweight package. This makes it an excellent choice for welders who need to work on various outdoor projects. It can run on 96-265V 50/60 Hz power, so there's no need to worry about not having the suitable power. The machine also features power factor correction technology, which provides multiple advantages such as energy-saving and wider input voltage. In foot pedal torch operation mode, the CT2050 offers remote control options such as a pedal remote and a welding torch remote control (Foot pedal is not included). Additionally, the CT2050 comes with a built-in compressor, so welders can start cutting without an extra air compressor.

- Multi-process capability for AC/DC TIG, AC/DC Pulse TIG, Stick, and Cut operations in one lightweight package

- Wide voltage range, can run on 96-265V 50/60 Hz power

- Power factor correction technology for energy-saving and wider input voltage

- Remote control options available in foot pedal torch operation mode

- Built-in compressor for easy portability and outdoor projects

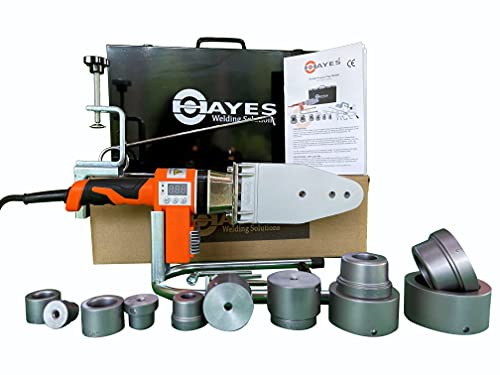

4. Hayes Digital Socket Fusion Pipe Welder Tool Complete Kit Pro (Up To 2 In.)

Introducing the versatile pipe welding machine which can weld pipes made of PPR, HDPE, MDPE, PE, and PB with ease. The machine comes with a working range of ½ inch CTS to 2 inches IPS and six heating faces, six chamfer tools, and six cold rings of different sizes (1/2 inch IPS to 2 inches IPS) to make the welding process efficient and effortless.

With a power of 800W and a voltage range of 110V -50/60 Hz, the machine can display the temperature in Fahrenheit, making it convenient for the user. The machine's sturdy built ensures durability, reliability, and efficient operation. It's easy to use, and the user manual guides step-by-step on how to operate the machine.

The machine's compact size and light-weighted design make it perfect for welding pipes at construction sites, homes, and other outdoor locations. Whether the user is a professional or a DIY enthusiast, this machine is a must-have for welding different types of pipes.

- Can weld pipes made of PPR, HDPE, MDPE, PE, and PB

- Comes with six heating faces, six chamfer tools, and six cold rings of different sizes

- Compact size and light-weighted design make it easy to carry and use at different locations

- Displays temperature in Fahrenheit, making it convenient for the user

- Sturdy built ensures durability, reliability, and efficient operation

5. Extreme Welder's Safety Combo

The G5-01 welding filter is a versatile and innovative product that offers a comfortable and clear view for most types of arc welding. It features the 3M Natural Colour technology which provides a lighter, more detailed and colourful view. The filter offers variable dark shades 5, 8-13 and tack welding comfort mode, and comes with a big (104 x 170 mm), clear protective visor that offers excellent views up, down and peripherally.

To further enhance the comfort of the user, the G5-01 helmet airflow optimization system allows for directing the airflow to either the face or visor, or somewhere in-between. This feature gives the user more control over their comfort during welding. Additionally, the helmet can be re-configured using various optional accessories, such as task light assembly, 1000 Assigned Protection Factor (APF) assembly, high-visibility head cover, leather head/neck cover, and more. The user can customize the helmet to find the right coverage and protection for their specific needs.

- 3M Natural Colour technology provides a lighter, more detailed and colourful view

- Variable dark shades 5, 8-13 and tack welding comfort mode

- Big (104 x 170 mm), clear protective visor with excellent views

- G5-01 helmet airflow optimization system allows for directing the airflow for more comfort

- Optional accessories available for customization

6. Hayes Digital Socket Fusion Pipe Welder Tool Kit Pro (Up To 2 In.)

Introducing the versatile and efficient pipe welding machine, capable of welding pipes made of PPR, HDPE, MDPE, PE, and PB. With a working range of 1/2 inch CTS to 2 inches IPS, it comes equipped with six heating faces in sizes that include 1/2 inch IPS, 3/4 inch IPS, 1 inch IPS, 1-1/4 inch IPS, 1-1/2 inch IPS, and 2 inches IPS. The voltage range of this machine is 110V-50/60 Hz with a power output of 800W. The temperature is displayed in Fahrenheit, reaching a maximum of 554°F.

This welding machine is perfect for both professional and home use, offering a reliable and efficient way to weld pipes of different materials and sizes. The six heating faces provide versatility and convenience, allowing users to choose the right size for the job. The temperature display makes it easy to monitor the welding process, ensuring a secure and precise weld every time. With its sturdy construction and powerful performance, this pipe welding machine is a must-have for any plumber or DIY enthusiast.

In conclusion, this pipe welding machine is a reliable, efficient and versatile tool for welding pipes of different materials and sizes. With its wide working range, six heating faces, and precise temperature control, it is perfect for both professional and home use. Its durable construction and powerful performance make it a must-have for anyone who needs to weld pipes.

- Versatile and efficient welding machine for pipes made of different materials and sizes

- Six heating faces in different sizes provide versatility and convenience

- Temperature display allows easy monitoring of the welding process

- Sturdy construction and powerful performance ensure reliable and secure welds

7. Bluerock Tools Model Cg-211y Manual Pipe Cutting Machine – Track Torch Burner

The Manual Chain Pipe Cutting Machine is a versatile tool that can cut pipes up to 24 inches in diameter without the need for electricity. It features an 87-inch chain link that can be adjusted to fit different pipe sizes.

This cutting machine comes with a complete torch head assembly that includes standard B-fittings and valves. The torch holder assembly is designed with an adjustable straight or beveling angle mount and bars, which allows for precise and efficient cutting.

The cutting tips that come with this machine include #1, #2, #3 Acetylene GO2, which are similar to Airco brand. Additionally, this unit is also compatible with Propane Tips for added convenience. The machine also includes small and large wheel sets for both small and large pipes.

Overall, the Manual Chain Pipe Cutting Machine is a reliable and efficient tool for cutting pipes of various sizes without the need for electricity. Its adjustable torch holder assembly and cutting tips make it highly versatile, while its small and large wheel sets provide added convenience.

- Does not require electricity, making it highly portable and easy to use in any environment

- Comes with a complete torch head assembly with standard B-fittings and valves, saving users time and money

- Adjustable torch holder assembly and cutting tips make it highly versatile, allowing users to cut pipes of different sizes and shapes

- Small and large wheel sets for both small and large pipes provide added convenience

- – May not be suitable for cutting pipes larger than 24 inches in diameter

- – Requires manual effort to operate, which may not be ideal for large projects

8. Weldpro's 5-In-1 Welding Marvel

The Weldpro model 210 LCD is an advanced multi-function welder capable of delivering precision welding results. It has a color LCD display that makes it easy to set and read the amperage and wire speed for repeatable welds every time. The unit is designed to perform MIG, Stick, and Lift TIG welding all from a single compact and space-saving device. The MIG 210LCD is a synergically designed welding machine and offers the option for independent voltage and wire speed control. This feature allows you to have more control over your welding process, making it possible to achieve even more precise results.

This versatile welder is fitted with added features such as Run-In, Spot Weld, Gas Choice, Synergic or Full Manual controls which make it convenient to customize the welding process to your preferences. In addition, in Stick (MMA) mode, it has on-screen electrode type choices, Hot Start, and Arc Force which makes it more adaptable to different welding conditions.

The Weldpro model 210 LCD welding amperage ranges from 230V: MIG: 40-200A; MMA: 20-180A; TIG: 20-180A. It has a 30% duty cycle at 200 Amps, making it suitable for high-performance welding tasks. The unit's VRD (Voltage Reduction Device) ensures high-temperature and overload protection with an indication feature. The welder is equipped with user-adjustable inductance settings, giving users the flexibility to modify the welding parameters to match the type of material they want to weld.

With an option for total independent voltage and wire speed control, color LCD easy-to-read displays, and added features like Run-In, Spot Weld, Gas Choice, the Weldpro model 210 LCD is a welding machine that is perfect for professionals who need precise welding results every time.

- Versatile and multi-functional

- Easy to use and operate

- Compact and space-saving design

- Allows users to perform MIG, Stick, and Lift TIG welding

- User-adjustable inductance settings for welding different materials

- – May not be suitable for beginners

9. Forney Easy Weld 261, 140 Fc-I Welder, 120v, Green

The EASY TO USE-140 FC-I MIG machine is an excellent entry-level welder for those who are just starting out. It uses 0.30 flux core wire and has infinite voltage and wire feed speed control, which allows you to dial in the perfect weld. With a maximum output of up to 140 Amps, this welder can weld mild steel up to 1/4 inch plate. It is lightweight, weighing only 19 lbs, which makes it easy to carry to any Do-It-Yourself, Maintenance, Repair, Metal Fabrication and Hobbyist project. The all-metal case is rugged and built to withstand daily use, making it durable and long-lasting. The welder is big enough to handle 2 and 10-pound rolls of wire. The EASY TO USE-140 FC-I MIG machine comes with an 8' MIG gun, 8' ground clamp, integrated handle with torch wrap, and a 20A-15A adapter. It is backed by a 12-month warranty.

The product specifications of the EASY TO USE-140 FC-I MIG machine are as follows: Dimensions: 16.75" (425.45 millimeters) x 8.125" (206.38 millimeters) x 12" (304.8 millimeters), Weight: 19 lbs. (8.62 kilograms), Gasless/flux-core welding only, Portable, Torch wrap, Infinite voltage and wire feed speed control, 120-volt input, 140 AMP output, Welds up to 1/4 in. (6.35 millimeters), Handles .030 in. or 0.35 in. wire, Includes: 8' MIG gun, 8' ground clamp and 20A – 15A adapter, Duty Cycle 30% @ 90A.

To get the most out of the EASY TO USE-140 FC-I MIG machine, it is recommended to use the following accessories: Contact Tips (60170, 60171 and 60172), Welding Nozzles: (85336 and 85337), Diffuser: (85339), Flux Core MIG Wire: (42300 and 42301), Anti-Spatter Spray: (37030), Nozzle Gel: (37031). Click on the (BY FORNEY) name above in blue under the title to view our full catalog of Welders, Abrasives, Chain/Wire Rope, Tools and more!

- Infinite voltage and wire feed speed control allows for precise welding

- Lightweight and portable design makes it easy to carry to any project

- Rugged all-metal case is built to withstand daily use

- Comes with an 8' MIG gun, 8' ground clamp, integrated handle with torch wrap, and a 20A-15A adapter

- Can weld mild steel up to 1/4 inch plate

- Backed by a 12-month warranty

- – Gasless/flux-core welding only

- – Duty cycle of 30% at 90A may not be sufficient for some projects

10. Lincoln Flux Core Welder: Portable Power For Small Jobs

The Century FC90 flux-cored wire feed welder is the perfect machine for small welding jobs. It can be plugged in anywhere with a 120V input power. The machine is lightweight and portable, making it ideal for maintenance and mobile welders. Its small and lightweight inverter design and shoulder strap allow for easy portability. The automatic thermal protector shuts off the output until the machine cools to a normal operating temperature, ensuring safety. The easy-to-turn control knobs make it convenient for users to fine-tune welding parameters. The spool of wire can be conveniently loaded on top of the machine, making it easier for users to access. The inverter power source makes the machine more efficient to operate and provides smoother weld characteristics compared to traditional welders. The machine has an infinite welding voltage, which allows fine-tuning of weld characteristics. It has a 30% duty cycle at 80 Amp and a 30-90 Amp range, making it perfect for DIY projects, hobbyists, home repairs, and more.

- Lightweight and portable

- Automatic thermal protector ensures safety

- Easy-to-turn control knobs for convenience

- Inverter power source makes it more efficient to operate

- Smaller and more lightweight inverter design

- Shoulder strap for easy portability

- Conveniently load spool of wire on top of the machine

- Infinite welding voltage allows fine-tuning of weld characteristics

- Ideal for small welding jobs

- – Not suitable for heavy-duty welding jobs

Best Chinese Tools For Welding FAQs

How do Chinese welding tools compare to other welding tools in terms of quality and durability?

Chinese welding tools have been gaining popularity in recent years due to their affordability and accessibility. However, their quality and durability have been a subject of debate in the welding industry. It is important to note that not all Chinese welding tools are of low quality, as there are some reputable brands that produce high-quality products.

In terms of quality, Chinese welding tools are often criticized for their inconsistent performance and lack of precision. This can be attributed to the use of substandard materials and manufacturing processes. However, some Chinese brands have been making efforts to improve the quality of their products by investing in advanced technology and skilled labor.

As for durability, Chinese welding tools have been known to have a shorter lifespan compared to other welding tools. This can be attributed to the use of cheaper materials and less rigorous quality control measures. However, this is not always the case, as some Chinese manufacturers have been able to produce welding tools that are both durable and affordable.

In conclusion, while Chinese welding tools may not always match up to the quality and durability of other welding tools, it is important to consider the brand and specific product before making a judgment. With the right research and due diligence, it is possible to find high-quality and durable Chinese welding tools at an affordable price point.

How do Chinese welding tools differ from other welding tools in terms of price and availability?

Chinese welding tools are known for their competitive pricing compared to other welding tools in the market. One of the main reasons for this is the lower cost of labor in China, where these tools are mainly manufactured. Additionally, China has a huge manufacturing industry, and this translates to a high availability of welding tools in the market.

Despite the lower cost, Chinese welding tools are still of high quality and are manufactured in compliance with international standards. Chinese manufacturers have invested heavily in research and development to improve the quality of their products and meet the needs of their customers.

Another factor that sets Chinese welding tools apart is their versatility. They are designed to work with a wide range of materials, including aluminum, steel, and other metals. This makes them an ideal choice for welding professionals who handle different welding tasks.

Overall, the affordability, availability, and quality of Chinese welding tools make them a popular choice for welders around the world. However, it's essential to do your research and purchase from reputable manufacturers to ensure you get the best value for your money.

What are the advantages and disadvantages of using Chinese welding tools in welding applications?

The use of Chinese welding tools in welding applications has its own set of advantages and disadvantages. One of the advantages of using Chinese welding tools is that they are generally cheaper than their counterparts from other countries. This makes them a popular choice among budget-conscious welders. Additionally, Chinese welding tools are known for their durability and reliability. They can withstand harsh welding conditions and last for a long time.

However, there are also some disadvantages to using Chinese welding tools. One of the main concerns is the quality of the products. While some Chinese welding tools are of high quality, others may be of inferior quality. This can lead to issues such as weld defects and safety hazards. Another concern is the lack of standardization in Chinese welding tools. This can make it difficult for welders to find the right tools for their specific needs.

In conclusion, the use of Chinese welding tools in welding applications has its pros and cons. While they are generally cheaper and durable, issues related to quality and standardization can arise. Welders should carefully consider their options and choose the tools that best suit their requirements.

What are the best practices for using Chinese welding tools and ensuring their optimal performance?

When it comes to using Chinese welding tools, there are a few best practices that you should keep in mind in order to ensure their optimal performance. First and foremost, it's important to choose high-quality tools from reputable manufacturers. Look for tools that are made from durable materials and have been thoroughly tested to ensure their reliability and effectiveness.

Once you have the right tools, it's important to use them properly. This means following the manufacturer's instructions carefully and taking the necessary safety precautions to prevent injury or damage to your equipment. It's also important to regularly inspect and maintain your tools to ensure that they are in good working order.

Another key best practice is to stay up-to-date with the latest welding techniques and technologies. Attend training sessions and workshops to learn about new tools and techniques that can help you improve your welding skills and achieve better results.

Finally, it's important to work with a team of experienced professionals who can provide guidance, support, and feedback as you work with your Chinese welding tools. By following these best practices, you can ensure that your tools perform optimally and that you achieve the best possible results in your welding projects.

What are the most commonly used Chinese welding tools in the welding industry?

In the welding industry, Chinese welding tools have gained popularity due to their high-quality and cost-effectiveness. The most commonly used Chinese welding tools in the welding industry include welding machines, welding electrodes, welding wires, welding torches, welding helmets, and welding gloves.

Welding machines are essential in the welding industry, and Chinese welding machines have become popular due to their durability and reliability. Welding electrodes are also widely used in the welding industry, and Chinese electrodes are known for their high-quality and low cost.

Welding wires are another essential welding tool, and Chinese welding wires are known for their excellent performance and low cost. Welding torches are also widely used in the welding industry, and Chinese torches are known for their robustness and precision.

In addition to these tools, Chinese welding helmets and gloves are also popular due to their high-quality and affordability. Overall, Chinese welding tools have become a popular choice in the welding industry due to their excellent performance, cost-effectiveness, and reliability.